What are the structural components of Pogo Pins, Explore benefits and usage in electronic devices to quickly grasp this essential connector.

Introduction to Pogo Pins

Pogo Pins, also known as spring-loaded pins, are essential connectors featuring a spring mechanism designed to provide electrical connections, especially in high-frequency plug-and-unplug scenarios. With their robust design, Pogo Pins excel in diverse applications, ensuring dependable connections in both consumer electronics and healthcare.

Before diving into their applications, it’s crucial to understand What are the structural components of Pogo Pins, as this knowledge lays the foundation for further discussion.

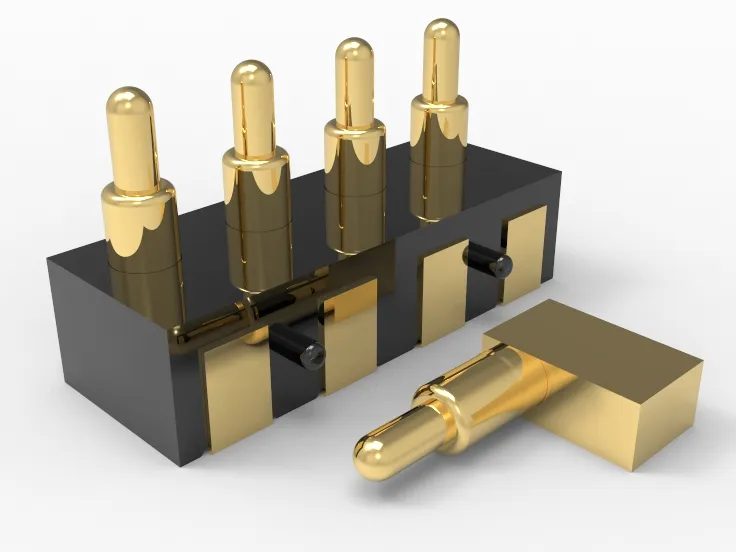

Main Components of Pogo Pins

What are the structural components of Pogo Pins? They primarily consist of several key parts:

- Pin Body: The pin body is the main part of the Pogo Pin, typically made from conductive materials such as copper, nickel, or gold to ensure optimal electrical conductivity. The design of the pin body can impact both electrical performance and mechanical strength, with common shapes including cylindrical and conical.

- Spring: The spring is a vital component of the Pogo Pin, responsible for providing the necessary pressure to ensure a solid electrical contact. The material and shape of the spring directly affect the contact performance and durability of the Pogo Pin. Common materials include stainless steel and nickel alloys, which offer excellent elasticity and corrosion resistance.

- Housing: The housing, usually made of plastic or metal, serves to protect the pin body and spring while also providing some level of insulation. The housing design plays a vital role in ensuring Pogo Pins stand the test of time.

- Insulating Material: In certain designs, insulating materials are employed to prevent short circuits and interference. These materials provide electrical isolation between different parts of the Pogo Pin, ensuring safe and reliable connections.

- Contact Surface: The contact surface is the part of the Pogo Pin that directly interfaces with other circuits or devices. It is typically designed to maximize contact area, thereby reducing contact resistance. A well-designed contact surface can significantly enhance signal transmission efficiency.

Understanding: what are the structural components of Pogo Pins? It allows us to further analyze the specific functions and impacts of each part.

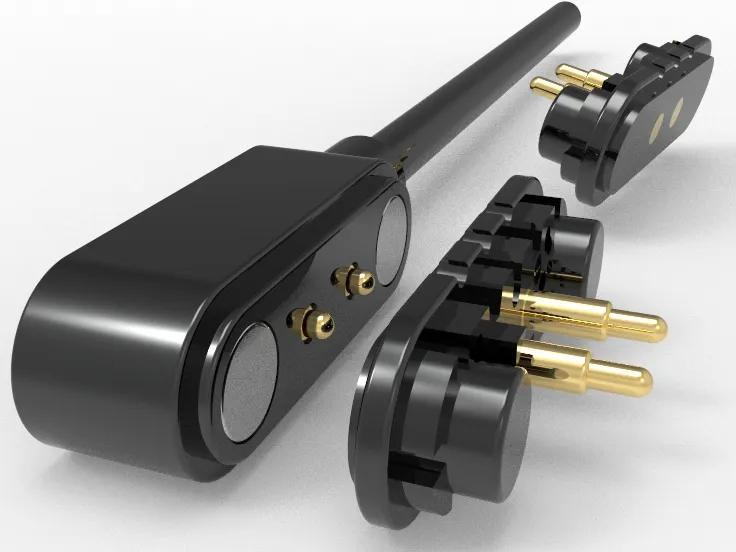

How Pogo Pins Work?

The functionality of Pogo Pins is closely tied to their structure. At the heart of a Pogo Pin is its spring mechanism. When the Pogo Pin is pressed against a contact point, the spring compresses, exerting pressure on the contact surface to ensure a solid electrical connection.

This design not only enhances the reliability of the connection but also allows the Pogo Pin to withstand frequent plugging and unplugging. The structural components of the Pogo Pin determine its operational performance, making it crucial to pay special attention to the materials and shapes of each component during the design process.

Applications of Pogo Pins

The unique structure of Pogo Pins makes them suitable for a variety of fields. Understanding What are the structural components of Pogo Pins can help us better appreciate its applications. Here are some major application areas:

- Consumer Electronics: With their compact design, they seamlessly fit into devices, delivering power and information effortlessly. These devices demand high reliability and durability in their connections, and Pogo Pins are perfectly equipped to meet those requirements.

- Medical Equipment: Their robust design is vital for maintaining the safety and efficiency of critical medical instruments. Medical equipment often requires long-term stable operation, and the high reliability of Pogo Pins makes them an ideal choice.

- Industrial Automation: Pogo Pins are used in robots and automated systems to achieve quick electrical connections and disconnections, making them suitable for a range of complex industrial applications.

- Battery Connections: In battery assembly, Pogo Pins can connect batteries to circuit boards, ensuring efficient power transfer.

Advantages of Pogo Pins

The design of Pogo Pins gives them several unique advantages. Understanding the structural components of Pogo Pins helps us better appreciate these benefits:

- High Reliability: Thanks to their spring mechanism, Pogo Pins maintain excellent contact performance during high-frequency plugging and unplugging, ensuring stable signal transmission.

- Flexibility: Whether it’s for compact gadgets or larger machinery, there’s a Pogo Pin solution for every need. This flexibility allows Pogo Pins to be widely used across different industries.

- Durability: High-quality materials and spring design ensure the longevity of Pogo Pins, reducing maintenance costs even with frequent use.

- Compact Design: This makes them ideal for devices where every millimeter counts, ensuring reliable performance without sacrificing space.

How to Choose the Right Pogo Pin?

When selecting a Pogo Pin, several factors come into play, including the application environment, required current, and voltage. Knowing the parts of a Pogo Pin empowers you to make smarter decisions. For instance, in high-current applications, it’s essential to choose a thicker pin body and the right spring pressure to ensure optimal performance.

Additionally, Temperature and humidity play a key role in keeping your Pogo Pin functioning smoothly.

Future Trends of Pogo Pins

As technology continues to advance, the applications of Pogo Pins are expanding rapidly. In the future, we may see innovations in the design of Pogo Pins, particularly in materials and structure, to meet more demanding application requirements. For example, the development of high-temperature-resistant spring materials or the integration of additional functionalities into Pogo Pins could enhance their performance significantly.

Moreover, As electric cars and renewable technologies gain traction, Pogo Pins are in higher demand than ever. These emerging applications require efficient and reliable connection solutions, and Pogo Pins are well-positioned to meet this demand.

Market Prospects for Pogo Pins

Pogo Pins hold a significant position in the global electronic components market. The growing trend of IoT and smart home technology is driving an even greater demand for Pogo Pins.

In the coming years, the application areas for Pogo Pins will likely continue to expand, making them an indispensable connection solution in the electronics industry. Understanding the components of Pogo Pins can help companies better seize market opportunities in technology innovation and product development.

Conclusion

In summary, the structural components of Pogo Pins are crucial to their performance and applications. By understanding What are the structural components of Pogo Pins, we can gain deeper insights into their working principles, application scenarios, and market potential.

As technology evolves, the design and application fields of Pogo Pins will keep expanding, providing more reliable connection solutions for the electronics industry. We hope this article helps you better understand Pogo Pins and offers valuable guidance for your design and selection processes.