What is a Multi point Inspection? Learn How Johoty Guarantees Top-notch Quality and Consistency in Pogo Pins, Satisfies strict Project and Budget

Introduction: What is a Multi point Inspection?

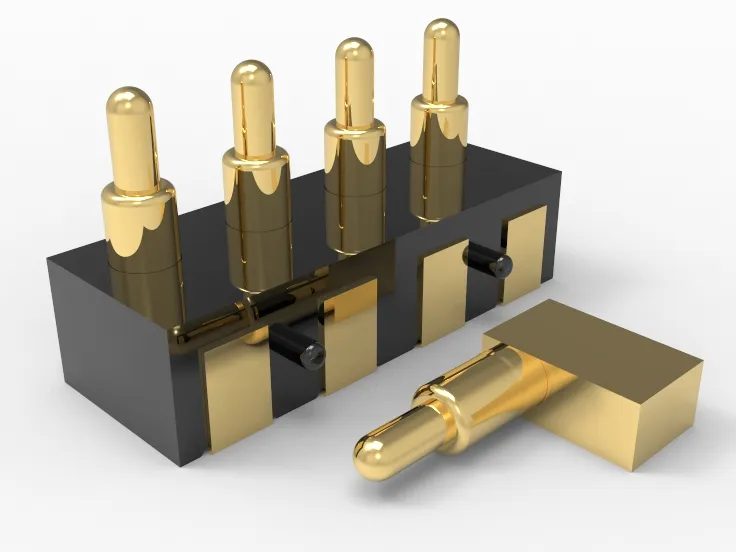

In modern electronic component manufacturing, precision and consistency are key to ensuring product quality. With high-precision connectors like Pogo Pins, even the tiniest flaw can affect how well the entire system works and how long it lasts.

To tackle this challenge, Johoty has implemented industry-leading Multi Point Inspection technology. This innovative quality control method rigorously checks every critical stage of production, ensuring that each Pogo Pin or Pogo Pin Connector leaving our factory meets strict standards for stability and reliability.

Whether dealing with complex projects or budget constraints, Johoty’s Multi Point Inspection process delivers unmatched quality assurance and value enhancement.

The Basics of Multi Point Inspection: What is a Multi point Inspection?

1. Definition: What is a Multi point Inspection?

Multi Point Inspection is a vital quality control technique in precision manufacturing. Our process guarantees consistent and accurate products by inspecting them at multiple points throughout production.

This method relies on advanced testing equipment to monitor and analyze key parameters like size, shape, and performance of products such as Pogo Pins in real time. This ensures that each item adheres to strict quality standards across various dimensions.

2. Working Principle: What is a Multi point Inspection?

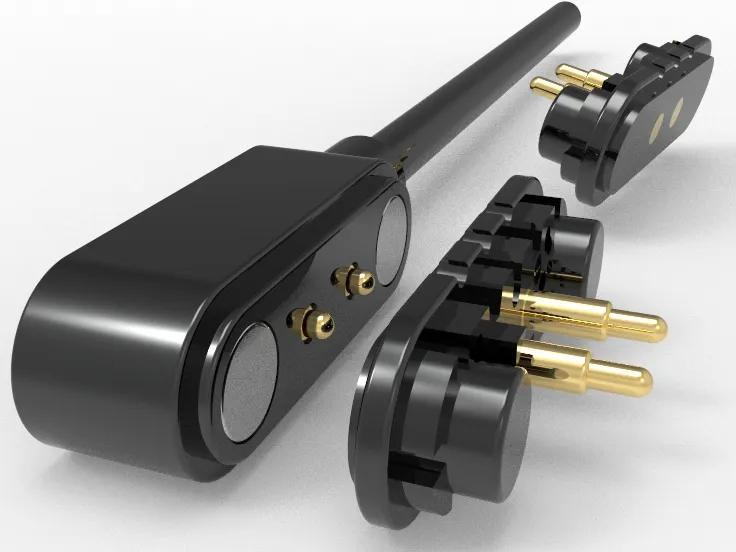

Multi Point Inspection integrates an automated system equipped with sensors, cameras, or lasers positioned at different points along the production line. Each checkpoint measures specific product parameters—such as length, diameter, surface roughness, and electrical conductivity—providing real-time feedback to a central control system.

Any deviation, no matter how small, is immediately recorded and adjustments are made on the spot, preventing defective products from moving further down the line.

3. Advantages: What is a Multi point Inspection?

- Ensuring Consistency: Multi Point Inspection detects subtle differences across various product dimensions, ensuring batch consistency.

- Improving Efficiency: Automating inspections cuts down on mistakes and boosts overall production efficiency.

- Cost Reduction: Early detection and correction of potential issues lower the defect rate, reducing production and quality control costs.

- Meeting Stringent Requirements: This technology meets the rigorous quality demands for high-precision products like Pogo Pins, even in challenging projects with tight budgets.

Johoty’s Multi Point Inspection Process: What is a Multi point Inspection?

1. Raw Material Inspection: What is a Multi point Inspection?

- Before production begins, Johoty conducts a thorough visual inspection of incoming raw materials to ensure no visible defects such as oxidation or scratches. We then use precision measuring tools and equipment to test critical physical properties like hardness, thickness, conductivity, and corrosion resistance. Each parameter is customized based on the specific Pogo Pin design requirements, ensuring all materials fully meet the specifications.

- In addition, Johoty performs chemical composition analysis using advanced equipment such as spectrometers. This multi-point sampling method ensures that the materials meet industry standards and any specific customer requirements, preventing any quality risks arising from material impurities. After completing the initial inspection, materials undergo stress and fatigue testing to verify their stability under high pressure and extended use, laying a solid foundation for the production of Pogo Pins.

- By adhering to this rigorous multi-point raw material inspection process, Johoty minimizes the risk of material defects and ensures that every stage of Pogo Pin production is carried out under optimal conditions, providing clients with high-quality, cost-effective custom solutions.

2. In-Process Inspection: What is a Multi point Inspection?

- Multi Point Inspection during production is the cornerstone of this quality control system, covering every stage from machining and assembly to final testing. During the machining phase, Johoty monitors and measures each production node in real-time. Automated inspection equipment meticulously checks critical parameters such as dimensional tolerances, machining accuracy, and plating thickness, ensuring that each part matches the design blueprint. For critical processes, like spring assembly or housing turning, Johoty conducts multiple measurements to maintain precision and consistency.

- In the assembly phase, Johoty’s Multi Point Inspection system strictly monitors component alignment, ensuring precision in the fit between the spring, probe, and housing. Force tests ensure that contact force and spring rebound meet design specifications. Any component that fails to meet the standard is either discarded or reworked.

- Additionally, Johoty employs automated visual inspection systems to perform multi-angle, Multi Point Inspections of finished products, detecting even the smallest surface flaws or manufacturing defects like uneven plating or deformation. This comprehensive inspection ensures that each batch of Pogo Pins meets both visual and functional standards.

- During production, Johoty carries out stress and compression tests to mimic how the products will perform in real life. This guarantees that Pogo Pins maintain high performance and durability during prolonged use. The Multi Point Inspection process not only enhances precision and efficiency in manufacturing but also significantly reduces defect rates, helping clients maintain the highest quality while keeping project costs in check. Each Pogo Pin that passes through Johoty’s inspection represents industry-leading quality and reliability.

3. Final Product Inspection: What is a Multi point Inspection?

Precision Component Checks

- Before assembly, each component undergoes a detailed inspection. We check the stability of solder joints, the strength of connections, and the geometric accuracy of each part to ensure that they fit together seamlessly, creating a flawless final product.

Strict Dimensional Tolerance Control

- Using high-precision measuring equipment, we strictly monitor the dimensions of each Pogo Pin. Our tolerance standards far exceed industry norms, ensuring that every product is manufactured exactly to design specifications, avoiding even the slightest dimensional deviations.

Comprehensive Functional Testing

- Every Pogo Pin goes through a comprehensive set of tests, including electrical performance, durability, and environmental adaptability. By replicating real-world situations, we check that our products hold up and work perfectly in different environments.

Random Sampling Inspections

- To further enhance quality assurance, Johoty conducts random sample inspections from each production batch. A percentage of products are selected for detailed quality checks to ensure overall batch consistency and reliability.

Final Quality Review

- After all testing is complete, our quality review team conducts a final inspection of each product. We carefully document all test results, and only after verifying that everything is in order, do we release the products to the market. This process guarantees that every product meets the highest quality standards.

Customer Feedback for KAIZEN

- We use customer feedback as a key tool for making our products better. We incorporate all feedback into our quality enhancement process, continuously optimizing our inspection methods and product quality to better meet market demands.

Case Study: What is a Multi point Inspection?

1. Successful Application in High-Precision Medical Devices

Background:

- A leading global medical device manufacturer required Johoty to provide high-precision Pogo Pins for heart monitoring equipment. These devices needed to maintain high stability and reliability in extreme environments.

Challenge:

- We were tasked with delivering Pogo Pins that could operate reliably under harsh conditions such as high temperatures and humidity, while ensuring long-term electrical connection stability.

Solution:

- Johoty employed Multi Point Inspection techniques, including functional and environmental adaptability tests. We simulated extreme conditions like high heat and humidity, ensuring each batch of Pogo Pins maintained stable electrical performance over time. Through precise testing and durability assessments, we guaranteed that the Pogo Pins met the client’s strict standards.

Execution & Results:

- All Pogo Pins successfully passed the client’s stringent testing, meeting their high standards. The client expressed great satisfaction with the quality of our Pogo Pins and inspection process, leading to a long-term partnership and enhancing our market reputation.

2. Breakthrough in Aerospace Equipment

Background:

- A leading aerospace company required high-reliability Pogo Pins for their satellite communication systems. These Pogo Pins needed to withstand strong vibrations and radiation exposure while maintaining stability.

Challenge:

- Ensuring that the Pogo Pins could operate reliably in extreme vibration and radiation environments posed a significant challenge for us.

Solution:

- Johoty incorporated vibration endurance and radiation resistance tests into the Multi Point Inspection process. We simulated the real-world vibration environment and conducted radiation tests to verify the long-term stability of the Pogo Pins. These tests ensured that the Pogo Pins remained reliable and consistent in extreme conditions.

Execution & Results:

- All Pogo Pins passed the rigorous tests and met the aerospace company’s high standards. The client praised our technical capabilities and stringent quality control, resulting in increased order volume and positive recommendations within the industry.

3. Success Case in Consumer Electronics

Background:

- A well-known consumer electronics company needed high-precision Pogo Pins for its latest smartphone, requiring reliable electrical connections in a compact design space.

Challenge:

- The Pogo Pins needed to maintain high precision and consistency within a very limited space to meet the device’s compact design and high-performance requirements.

Solution:

- Johoty applied precise dimensional measurements and component assembly checks within the Multi Point Inspection process. We used high-precision measuring equipment to strictly control the size of each Pogo Pin and conducted detailed assembly reviews to ensure that the product operated within the small tolerance range specified by the design.

Execution & Results:

- All Pogo Pins met the customer’s high-precision standards. The product received high praise in the market, and the customer expressed satisfaction with our precision control and service quality, significantly increasing their order volume in subsequent batches.

Conclusion:

Johoty has set a new benchmark in Pogo Pin quality control with its comprehensive Multi Point Inspection process. Through this rigorous inspection method, we ensure that every Pogo Pin delivers exceptional performance and consistency, even under extreme conditions, meeting the demands of strict projects and budgets.

1. Core Advantages of Multi Point Inspection:

- Multi Point Inspection covers not only raw material inspection and production process monitoring but also comprehensive final product testing. This all-encompassing inspection approach ensures that Pogo Pins maintain a high level of quality control at every stage, preventing potential issues before they arise.

2. Ensuring Consistency:

- Through precise dimensional measurements, functional tests, and environmental adaptability assessments, Johoty guarantees that each batch of Pogo Pins meets strict consistency standards. Whether facing extreme environmental conditions or prolonged usage, our inspection process ensures product stability and reliability.

3. Meeting Customer Needs:

- Our Multi Point Inspection process showcases its adaptability and flexibility in meeting strict project and budget requirements. We tailor inspection plans based on customer needs and provide detailed data analysis and test reports to deliver the most fitting solutions.

4. Proven Success Cases:

- Johoty’s Multi Point Inspection process has proven its effectiveness through a series of successful case studies. From high-precision medical devices to aerospace applications and consumer electronics, our inspection method consistently meets the high standards of various industries.

5. Continuous Improvement and Innovation:

- Johoty continuously optimizes and upgrades our Multi Point Inspection process to keep pace with evolving market demands and technological advancements. Through ongoing innovation and process improvements, we are committed to delivering higher-quality, higher-performance Pogo Pins.

In summary, Johoty’s Multi Point Inspection process is not just a quality control method but also a reflection of our commitment to customers. Through this thorough and detailed inspection approach, we ensure that every Pogo Pin achieves top-tier quality and consistency, setting a new standard in the industry while meeting customer demands for stringent projects and budgets.