What is Durability Test? Discover How Johoty Conducts Rigorous Durability Tests to Ensure Pogo Pins Meet High Performance and Budget Requirements

Introduction

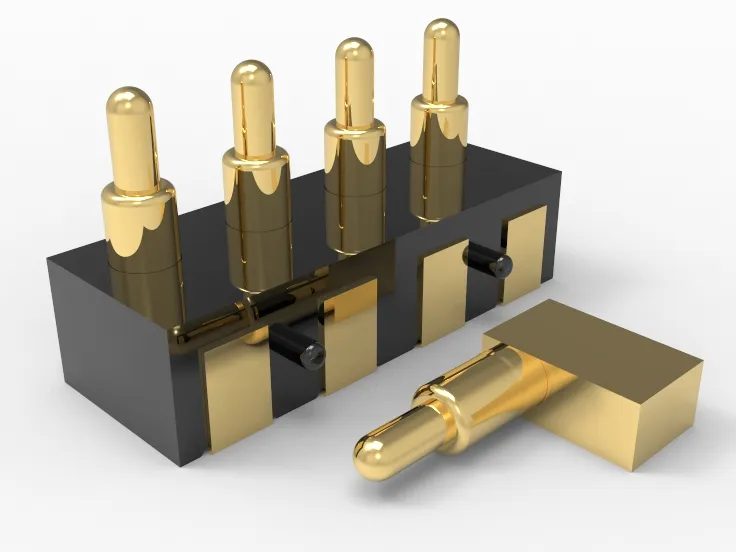

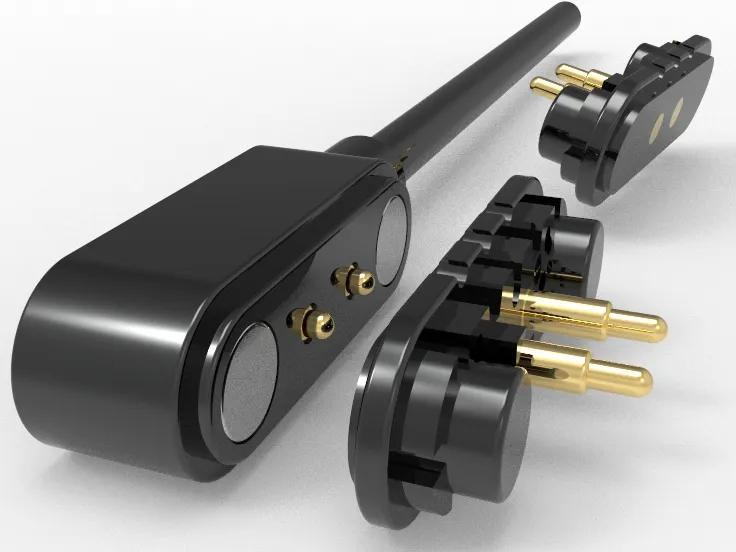

The durability and reliability of electronic devices are crucial. Pogo Pins, key connectors used in smartphones, robots, tablets, aerospace, and wearables, face increasing challenges due to complex environments and diverse user needs. Their durability has become a critical factor.

Durability Test is a scientific method to assess how well products perform over time, ensuring Pogo Pins excel even under extreme conditions. Johoty has implemented strict standards and advanced technologies in Durability Test to meet customers’ demands for high performance and budget. This process not only identifies potential defects but also ensures that every Pogo Pin is competitive in the market.

In this article, we’ll explore what Durability Test is and how Johoty ensures the high quality and reliability of Pogo Pins through systematic testing. By examining this process, you’ll understand why Durability Test is essential in the electronic connector industry.

The Importance of Durability Test: What is Durability Test?

1. The impact of Durability Test on the performance of Pogo Pins: What is Durability Test?

- Contact Resistance Stability: Testing reveals if contact resistance increases during repeated insertions, ensuring stable electrical performance over time.

- Mechanical Strength: Evaluates how Pogo Pins perform under mechanical stress, ensuring they don’t fail in high-pressure, high-frequency environments.

- Environmental Adaptability: Testing in various temperatures, humidity levels, and chemical conditions ensures Pogo Pins function reliably in diverse environments, reducing failures.

- Reusability Performance: Simulating repeated use ensures Pogo Pins maintain elasticity and recovery, supporting consistent functionality under frequent operations.

- User Experience Improvement: High-quality, stable Pogo Pins enhance user experience by minimizing device failures and increasing satisfaction.

2. How Durability Test Ensures Pogo Pin Longevity and Reliability: What is Durability Test?

- High-Frequency Insertion Testing: Repeatedly inserting Pogo Pins simulates real-world usage, confirming stable electrical connections over time.

- Extreme Environment Testing: Evaluating Pogo Pins under various temperatures, humidity, and vibrations ensures reliability, especially in demanding industrial applications.

- Mechanical Strength Testing: Applying different mechanical pressures checks Pogo Pins’ resistance to deformation or breakage, extending their lifespan.

- Corrosion and Oxidation Testing: Assessing Pogo Pins in humid or corrosive environments ensures long-term performance and reliability, critical for electronics.

3. Customer Expectations for Pogo Pin Durability: What is Durability Test?

- Long Lifespan: Customers want Pogo Pins to last under high-frequency use, reducing replacement needs and maintenance costs.

- Stable Performance: Reliability in various conditions is expected, avoiding device failures due to poor connections.

- Corrosion Resistance: In humid or corrosive settings, customers expect strong resistance for long-term stability.

- Impact Resistance: Pogo Pins should withstand mechanical stress and impacts without damage in extreme conditions.

- Consistency and Predictability: Customers desire consistent performance across mass production to prevent fluctuations due to individual differences.

Johoty’s Durability Test Process: What is a Durability Test?

1. Setting Up the Testing Environment: What is Durability Test

- Temperature Control: The testing environment is usually set between -40°C and +85°C to simulate extreme temperatures and their effect on Pogo Pins’ performance.

- Humidity Control: Relative humidity is set between 20% and 90% to evaluate how Pogo Pins perform under different humidity conditions.

- Vibration Testing: A vibration table simulates the vibrations experienced during transport to check the stability of Pogo Pins over extended use.

- Electrical Testing: Testing current and voltage are set to ensure Pogo Pins can handle normal electrical loads during actual use.

- Atmospheric Conditions: The testing environment should be dust-free to avoid interference from external contaminants.

2. Testing Standards and Methods: What is Durability Test

Johoty’s Pogo Pins undergo a rigorous Durability Test process to ensure high quality and stability:

Test Preparation

- Sample Selection: Multiple batches of Pogo Pins are randomly selected to ensure the test results are

representative and reliable. - Environmental Control: Tests are conducted in a temperature and humidity-controlled lab to eliminate external influences.

Mechanical Durability Test

Insertion and Removal Cycle Testing: What is Durability Test?

- Standard: Testing is based on IEC 60512-9-1.

- Method: An automated insertion and removal machine simulates real-life use, performing 10,000 cycles while monitoring contact performance.

- Evaluation: Changes in contact resistance are recorded to ensure it stays within acceptable limits after the cycles.

Tensile Testing:

- Standard: Testing follows ISO 13934-1.

- Method: Tension is applied in both vertical and horizontal directions for 30 seconds to test tensile strength.

- Evaluation: Ensure that Pogo Pins do not break or deform under applied tension.

Environmental Durability Test

High Temperature and Humidity Testing: What is Durability Test?

- Standard: Testing follows IEC 60068-2-30.

- Method: The product is exposed to high temperatures (70°C) and high humidity (93% RH) for 48 hours to simulate extreme conditions.

- Evaluation: Check for any changes in appearance or decline in contact performance.

Salt Fog Testing:

- Standard: Testing is based on ASTM B117.

- Method: The product is placed in a salt fog chamber for 48 hours to mimic humid and corrosive environments.

- Evaluation: Examine the Pogo Pins closely to spot any signs of rust or corrosion.

Electrical Performance Testing: What is Durability Test?

Contact Resistance Testing:

- Standard: Testing follows IEC 60512-2.

- Method: Use a high-precision multimeter to measure contact resistance, conducting multiple tests for consistency.

- Evaluation: Contact resistance should remain below 5 milliohms.

Insulation Resistance Testing:

- Standard: Testing is based on IEC 60167.

- Method: Apply a 500V DC voltage to measure insulation resistance.

- Evaluation: Insulation resistance should be above 100MΩ to ensure no current leakage occurs.

Data Recording and Analysis: What is Durability Test?

- Results Recording: Document detailed conditions, times, and results for each test to ensure data traceability.

- Data Analysis: Perform statistical analysis on all test data to determine if the Pogo Pins meet internal and international standards.

Report Generation

- Testing Report: Write a comprehensive report that includes testing methods, results analysis, and suggestions for improvement, providing strong support for product quality.

Through this rigorous Durability Test process, Johoty ensures its Pogo Pins maintain high performance and stability in various applications, earning customer trust and praise.

3. Testing Objectives: What is Durability Test

- Ensure Performance: Confirm that Pogo Pins don’t degrade in performance over time.

Enhance Reliability: Increase product reliability in extreme conditions through Durability Test. - Reduce Failure Rates: Identify potential design flaws to minimize the risk of product failures.

4. Importance of Testing: What is Durability Test

- Customer Trust: High standards in Durability Test strengthen customer confidence in Johoty products.

Market Competitiveness: Well-tested, high-quality products are more competitive in the market. - Brand Reputation: Consistently delivering quality Pogo Pins helps build a strong brand reputation.

Testing Equipment and Techniques: What is Durability Test?

1. Advanced Testing Equipment: What is Durability Test?

- Durability Test Machine: Johoty uses a high-precision machine that simulates how Pogo Pins are plugged and unplugged in real life. By setting specific plug-in and unplug cycles, the machine evaluates how much wear and tear the Pogo Pins experience in a controlled environment.

- Tensile Testing Equipment: This device measures how strong Pogo Pins are when stretched or compressed. It tests different levels of force to check the structural integrity and elasticity of the Pogo Pins.

- Temperature and Humidity Testing Chamber: Testing Pogo Pins under extreme conditions is crucial. Johoty uses this chamber to conduct tests at varying temperatures and humidity levels, ensuring the Pogo Pins perform reliably in all environments.

- Vibration Testing Platform: To assess how Pogo Pins hold up in vibrating conditions, Johoty uses this platform. It mimics the vibrations that might occur during transport or use, helping to evaluate the Pogo Pins’ strength and reliability.

- Microscope Inspection: After Durability Test, Johoty inspects the surface of Pogo Pins with a high-powered microscope to look for any tiny damage or wear, ensuring top-notch quality even at the microscopic level.

2. Innovations in Testing Techniques: What is Durability Test?

- Smart Testing System: Johoty has introduced a smart testing system that uses sensors to monitor the performance of Pogo Pins during durability tests in real time. This system automatically records data and analyzes parameters like plug-in cycles, pressure, and temperature for accurate results.

- Multidimensional Testing Platform: This platform allows Pogo Pins to be tested from various angles and directions, providing a comprehensive evaluation of their adaptability in real-life applications. By using this approach, we get a better understanding of the product’s performance than we do with standard tests that only go one way.

- Fatigue Life Prediction Model: Johoty has developed a data-driven model that predicts how Pogo Pins will perform over time by analyzing a lot of test data. This method enhances the scientific and forward-thinking aspects of product design.

- Environmental Adaptability Testing: In addition to mechanical stress, Johoty considers temperature changes and humidity effects during durability tests. This comprehensive approach effectively assesses how Pogo Pins perform under extreme conditions, ensuring reliability in various applications.

- Automated Fault Detection Technology: By using automated fault detection technology, Johoty can quickly identify any issues with Pogo Pins during testing. This technology uses machine learning to look at the results and send alerts if anything goes wrong, keeping the product stable.

Durability Test Data Analysis and Results: What is Durability Test?

1. How to Collect and Analyze Durability Test Data: What is Durability Test?

Test Preparation:

- Prepare multiple samples of Pogo Pins in a lab setting to ensure consistency during manufacturing. Establish testing standards, such as elasticity, contact resistance, and wear resistance.

Testing Methods:

- Mechanical Cycling Test: Perform repeated plugging and unplugging of Pogo Pins at different frequencies to simulate real-life wear.

- Temperature and Humidity Testing: Test Pogo Pins under extreme conditions to evaluate their performance in high heat, high humidity, and low temperature.

Data Collection:

- Use high-precision sensors and measuring instruments to record key data like contact resistance, insertion force, and extraction force for each plug and unplug cycle. Regularly document any changes in the appearance and functionality of the Pogo Pins during testing.

Data Analysis:

- Import the collected data into analysis software for statistical evaluation, including means, standard deviations, and variances. Use visuals, such as charts and graphs, to display how Pogo Pins react in different testing environments. Compare data before and after testing to assess whether durability metrics meet established standards.

Results Evaluation:

- Generate a detailed report based on the analysis results, assessing the Pogo Pins’ performance across various metrics, including lifespan predictions and failure mode analysis. Assess how reliable and stable they are in real-life situations to make sure they meet industry standards.

2. Impact of Durability Test Results on Pogo Pin Performance: What is Durability Test?

Contact Resistance:

- Tests show that after multiple cycles, the contact resistance of Pogo Pins remains within an acceptable range, indicating good conductivity. Stable contact resistance means more reliable signal transmission in actual use.

Mechanical Strength:

- After cyclic plug and unplug tests, the insertion force of the Pogo Pins remains stable, with no noticeable performance decline. This indicates their durability for high-frequency use, making them suitable for demanding applications.

Appearance Changes:

- After environmental testing, Pogo Pins show no significant corrosion or wear, maintaining a good appearance. This weather resistance ensures the product’s reliability in harsh conditions.

Lifespan Prediction:

- Based on data analysis, Johoty can provide lifespan predictions for Pogo Pins, giving customers clear usage guidance to help with purchasing decisions.

Conclusion:

Durability Test is a crucial part of the Pogo Pin production process. With rigorous testing methods and high-quality control standards, Johoty ensures that every product performs exceptionally in real-world applications. Choosing Johoty’s Pogo Pins means opting for high-performance products backed by industry quality assurance.