What is IP68 Waterproof? Explore Its Top 10 Applications & Benefits for Engineers. Learn How IP68 Enhances Durability in Harsh Use. Read More!

Introduction: What Is IP68 Waterproof?

What Is IP68 waterproof? In many of engineer’s designs, product durability and reliability under harsh conditions are strictly required. IP68 waterproof rating is the highest level of protection, you can place device in 1.5 meters of underwater for at least half an hour of normal operation. In industrial field, outdoor communication devices, and consumer electronics, IP68 waterproof can significantly improve performance and lifespan.

For engineers, IP68 waterproof is a technical challenge and a key to market competitiveness. It solves equipment failure in wet, dusty and extreme temperatures. It reduces maintenance costs and meets user expectations for high quality products.

So, what is IP68 waterproof? How is IP68 waterproof realized? In what areas is it most valuable? In this article, we will analyze top 10 applications of IP68 and its core benefits to provide inspiration for your next project.

Technical analysis of IP68 waterproof rating, What Is IP68 Waterproof?

The IP68 waterproof rating is the highest level of protection standard in engineering design, and the equipment can completely prevent dust and work for 30 minutes underwater at 1.5 meters. Engineers need to understand the technical details of IP68, as it directly relates to the reliability and market competitiveness of the product.

IP68 testing standard

IP68 is based on IEC 60529, and the equipment has high reliability in extreme environments, which is the cornerstone for engineers to design high durability products. It includes two key testing parts. 6 is a dust prevention test, which operates in a sealed dust environment to ensure that no dust enters the equipment. 8 is a waterproof test, which works for 30 minutes underwater at 1.5 meters, and the internal functions of the equipment are normal.

Key technologies and materials for achieving IP68 waterproof:

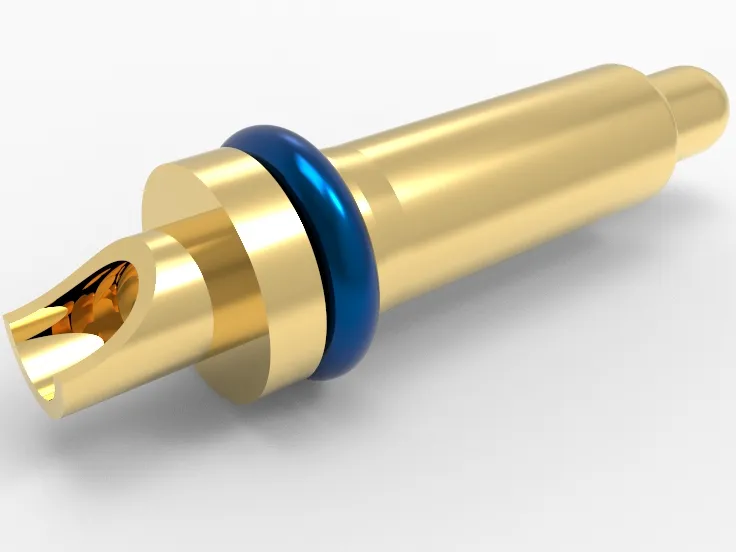

In terms of sealing technology, Johoty uses high-precision sealing rings and waterproof glue to ensure complete sealing of equipment joints. We also use waterproof breathable film, which can effectively balance device’s internal and external air pressure. This can prevent water vapor infiltration and avoid damage caused by pressure changes.

Johoty uses corrosion-resistant stainless steel and specialty plastics, as well as targeted composite electroplating, to effectively resist corrosive environments such as seawater and chemicals. Meanwhile, engineering design is the key to determining performance and price. We reduce the risk of water ingress by optimizing the internal structure of the equipment, minimizing seams and openings.

Read: 2 pin connector

Challenges and solutions faced by engineers in design:

Many times, equipment may be damaged due to pressure changes in deep water or high-altitude environments. Johoty’s effective solution is to use waterproof breathable membranes and pressure balancing valves. We tailor IP68 design according to customer needs to ensure device’s reliability and long-term use in specific environments.

At extreme temperatures, the expansion or contraction of materials can affect their sealing performance. We will all choose heat-resistant materials and conduct strict environmental testing. Utilize advanced technology and equipment to accelerate the process of pogo pin connector from design to mass production.

Through modular design and optimized production processes, Johoty helps customers find the best balance between performance and cost. IP68 design may increase costs, but based on professional design and high-quality materials, we can greatly improve lifespan. At the same time, we provide comprehensive testing from dust prevention to deep immersion to ensure that the product meets IP68 standards.

Read: 3 pin connector

IP68 pogo pin connector Applications and Benefits, What is IP68 Waterproof?

Smart home devices

Smart door locks, sensors, and cameras require long-term stable operation. Engineers often require Johoty’s pogo pin connector to maintain good electrical connection in harsh weather conditions. Therefore, the Pogo Pin connectors we manufacture on CNC machines can effectively cope with humidity, dust, and harsh weather conditions.

It has high durability, anti-corrosion, waterproof, dustproof, ensuring stable operation of smart devices in extreme environments. At the same time, it can extend the service life of customers’ equipment, reduce maintenance and replacement costs caused by environmental factors, and enhance the market competitiveness of equipment.

Read: 4 pin connector

Automotive Electronics

In car entertainment systems, autonomous driving sensors, ADAS, etc. require reliable connectors to ensure the stability of signal transfer. Require them to withstand extreme conditions such as high temperature and humidity. Completely waterproof and dustproof, able to withstand high temperatures, vibrations, and other environments inside and outside the car.

The automotive connectors designed by Johoty have high temperature resistance, corrosion resistance, and are suitable for in car electronic devices, ensuring the long-term stability of automotive electronic systems. Customers can obtain high-quality connections, reduce maintenance frequency, improve vehicle safety and driving experience.

Medical equipment

When facing environments contaminated with liquids and bacteria, medical equipment requires connectors with high precision and strong stability. The fully sealed IP68 pogo pin connector is waterproof and dustproof, effectively preventing liquids from seeping into the interior of the device.

Portable electrocardiogram monitors and implantable medical devices often use Johoty’s IP68 pogo pin connector. Has high anti pollution ability and meets strict hygiene requirements. It can greatly improve the safety of guest equipment and reduce cleaning and maintenance work. Meanwhile, the reliability and durability of medical equipment can also be significantly improved.

Read: 5 pin connector

Industrial Automation

It is often required to maintain stability in complex working environments, and connectors in industrial automation equipment need to support high-frequency signal transfer. The IP68 pogo pin connector can meet such requirements and has good signal transfer performance. At the same time, it has strong waterproof and dustproof capabilities, reducing equipment failure rates, lowering maintenance costs, and improving production efficiency.

Johoty’s IP68 Pogo Pin connector is designed to be compact and suitable for high-density applications. It can withstand oil stains, dust, and moisture, ensuring operation stability and durability of industrial equipment.

UAV

Engineers often require Johoty to provide lightweight and efficient connectors for drones to withstand high altitude, low temperatures, and humidity. Require us to ensure the stability of the drone’s signal and power. Improve the stability of drones under extreme conditions, reduce flight interruptions caused by connector failures, and enhance flight safety.

This IP68 waterproof pogo pin connector is corrosion-resistant, waterproof, dustproof for high altitudes in extreme weather. Meanwhile, Johoty often designs superior mechanical performance, corrosion resistance, and earthquake resistance for drones, ensuring their normal operation in complex environments.

Read: 6 pin connector

Military equipment

Johoty always provides the highest required connectors for military equipment, fully meeting the stable operation requirements of customers in extreme weather, high pressure, and vibration. For example, we provide American customers with a connection life of 200,000 times and a contact impedance of 15mΩ.

This IP68 waterproof pogo pin connector has extremely high waterproof and dustproof performance, and can adapt to harsh environments. Resistant to vibration and corrosion, able to maintain stability under harsh conditions. Improve the reliability of military equipment, reduce equipment failure rates, and enhance operational safety.

Johoty uses composite electroplating to ensure that the IP68 waterproof Pogo Pin connector does not peel or corrode in harsh environments. Excellent anti-interference and high-voltage resistance, suitable for various military fields, ensuring efficient operation of equipment in high-risk environments.

Consumer Electronics

Smart watches, Bluetooth earphones, electronic cigarettes, SOS wristbands, sports wristbands, etc. require miniaturized connectors, high-frequency signal transfer, and waterproof and dustproof capabilities. We can also understand that customers hope to improve the durability and reliability of consumer electronic devices and enhance the user experience.

Therefore, this IP68 waterproof pogo pin connector is mostly a small design with excellent waterproof and dustproof properties, suitable for precision electronic devices. Johoty provides a miniaturized IP68 water proof pogo pin connector with high precision, suitable for compact electronic products. This pogo pin ensures stable signal transfer and isn’t affected by its environment.

Read: 7 pin connector

Wearable devices

When exercising, swimming, or drifting, wearable devices require reliable and stable operation of connectors. They often require IP68 waterproof pogo pin connectors to be waterproof and dustproof, ensuring that wearable devices can function properly when in contact with water or sweat. After using Johoty’s IP68 water proof pogo pin connector, guests can enjoy a better sports experience.

The waterproof performance and service life of wearable devices can be effectively improved. This is due to our design, which makes the IP68 waterproof pogo pin connector highly waterproof. After repeated verification by European and American customers, they can be applied to various sports wearable devices.

Aerospace applications

Many American engineers are looking for connectors with extremely high requirements in space projects. It needs to withstand strict size limitations, weight control, extremely low temperatures, high radiation, etc. in the space environment. This IP68 waterproof pogo pin connector has extremely high resistance to high temperatures, radiation, low temperatures, and is waterproof and dustproof.

Johoty provides customized Pogo Pin connectors for the aerospace industry, including size, current, etc. It can meet the environmental requirements in space missions and ensure the normal operation of electronic devices inside the spacecraft. Ensure the high reliability of space equipment and avoid equipment damage or mission failure.

Read: 8 pin connector

Marine equipment

Waterproof and corrosion-resistant connectors enable marine equipment to be used for extended periods of time in saltwater environments without damage. This IP68 waterproof pogo pin connector is completely waterproof, dustproof, and resistant to salt corrosion in seawater. Customers can also extend equipment lifespan, enhance stability, significantly reduce maintenance costs.

At the same time, customers can ensure that marine equipment can work stably for a long time in harsh environments. How to achieve it? Johoty will use corrosion-resistant stainless steel 304 or 316, suitable for underwater sensors, marine exploration robots, etc.

Core advantage of IP68 design of pogo pin connector, What is IP68 Waterproof?

IP68 rating, impeccable protection design

Maintaining stable electrical connections is crucial for pogo pin connector in harsh industrial applications. The IP68 waterproof design can resist prolonged water immersion and complete dust intrusion. It can make the connector work stably under extreme conditions. This pogo pin connector can ensure the stability of your products in the marine industry in severe cold, high humidity environments and rainstorms. It can completely solve short circuits and faults caused by dust or moisture in ordinary connectors.

Read: 10 pin connector

Precise contact points, long-lasting contact force

Pogo pin connector relies on high-quality springs and gold-plated contact points to provide precise and stable electrical contact. Due to the precise spring force adjustment used in each pogo pin design, it ensures good contact performance even during frequent insertion and removal operations. Unlike traditional pin connectors, pogo pin can effectively withstand repeated insertion and extraction loads. It will not cause poor contact due to spring force fatigue, providing a more reliable long-term connection.

The perfect balance between flexibility and durability

IP68 pogo pin connector r is not limited to a standard size, and Johoty can customize multiple designs according to needs. In this way, Johoty’s pogo pins can fit different device types and connection methods of customers. With this flexibility, it can be applied to high-tech intelligent hardware, automotive electronics, medical equipment, and more. Combined with IP68 protection design, it can demonstrate excellent performance in extreme industrial settings and high-end consumer electronics.

Chemical corrosion resistance, challenging harsh environments

Engineers often need to consider the application of connectors in chemically corrosive environments during design. The IP68 pogo pin connector is made of advanced anti-corrosion materials and composite electroplating, ensuring long-term stability of the connector even in acidic or alkaline industrial environments. Its anti-corrosion ability ensures high safety in chemical factories and oil drilling platforms. Pogo pin can resist damage to its surface and internal structure caused by oil stains, corrosive liquids, etc., thus providing a long service life.

Read: 12 pin connector

Thermal stability, reliable even at extreme temperatures

Many engineering designs require connectors to work stably at extreme temperatures. Johoty fully considered the impact of extreme temperature differences when designing the IP68 pogo pin connector. In this way, this pogo pin connector can maintain excellent electrical performance between -40°C and+125°C. In the cold industrial environment of the Arctic or in high temperature summer power equipment, this pogo pin can operate stably, ensuring the safety and efficiency of the equipment.

Quick installation and maintenance, simplifying the production process

The design of IP68 pogo Pin Connector focuses on performance and also considers ease of installation and maintenance. Simple installation allows engineers to quickly install and debug equipment without the need for complex tools or installation processes. When large-scale production or equipment upgrades are required, this pogo pin connector can help customers reduce operating costs. Because it can achieve quick replacement and easy maintenance, effectively reducing downtime.

Why choose Johoty? What is IP68 Waterproof?

Excellent cost-effectiveness, reducing research and development costs

Although Johoty’s pogo pin connector has reached the top level of technology and quality in the industry, it always adheres to the principle of high cost-effectiveness. We strive to enable engineers to ensure high quality while significantly reducing research and development costs. For engineers, Johoty’s price and performance can enhance project competitiveness and reduce maintenance costs.

Read: Multiple pin connector

Super waterproof and dustproof performance, truly capable of handling extreme environments

IP68 waterproof is completely dust-proof and can work stably underwater for a long time. Johoty’s pogo pin connector features precision sealing design and high-quality materials. It has undergone strict waterproof testing and can work stably in outdoor high humidity, deep-sea environments, and high-pressure water flow during industrial cleaning processes.

This ultimate protection includes both exterior sealing and precise protection of internal circuits. Every Johoty’s pogo pin connector undergoes strict injection molding and sealant injection to prevent any moisture or dust from seeping in. It can ensure stable connection and avoid external interference causing device failure.

Extremely precise electrical performance, stable connection

Pogo pin connector is to provide stable electrical contact on core function. Johoty optimizes the contact spring force and elasticity of each pogo pin with its powerful research and development technology. In this way, it can achieve precise and stable current transfer with each contact. In the transfer of high-frequency signals and high current applications, Johoty’s connectors can ensure interference free and stable output.

This high-performance electrical connection is suitable for industrial automation, medical equipment, robots, etc. with high stability and precision. Johoty’s pogo pin connector can efficiently and reliably provide stable electrical connections in these situations, and the equipment can also operate consistently.

Read: Magnetic connector

Advanced materials and processes, high durability

Johoty is well aware that engineers have extremely strict requirements for materials under extreme temperatures, high humidity, and strong vibrations. Johoty’s pogo pin connector uses rigorously screened high-performance alloy materials and imported stainless steel. Based on compliance with electroplating, each pogo pin has strong corrosion, wear, and wear resistance.

At the same time, Johoty focuses on vibration and impact resistance, and pogo pin connectors can withstand severe vibrations from mechanical equipment or transportation vehicles. It will not experience looseness or poor contact. Our pogo pin connector is very popular in robots and autonomous vehicle, which greatly improves the service life.

Comprehensive customized services to meet various needs

Johoty can provide standard pogo pin connectors. Based on years of research and development experience, Johoty can provide customized IP68 waterproof pogo pin connectors according to specific needs Johoty can customize the number, length, spacing, connector material, contact force, and exterior design of pogo pins. In this way, each pogo pin connector can perfectly adapt to the customer’s personalized application.

This customization can improve device compatibility and reduce overall development costs. It avoids unnecessary waste of components and improves efficiency. In high-tech projects with precision design, Johoty’s personalized support is extremely important.

Read: Pogo Pins

Global certification and quality assurance, top tier trust worldwide

Johoty’s IP68 waterproof pogo pin connector strictly follows ISO standards, ROHS, REACH, ASTM. Every pogo pin or pogo pin connector meets the latest technological, electroplating technology, and environmental requirements. Most customers in Europe and America require the performance of IP68 water proof pogo pin connectors when choosing Johoty. Customers value our quality control system, competitive pricing, professional strength, and global service capabilities more.

With 23 quality control measures and stable supply capabilities, Johoty has become a long-term partner for many leading European and American companies. We are more inclined to provide high-quality IP68 water proof pogo pin connectors for our customers.

Powerful and professional technical support and services, quickly responding to needs

Our engineering clients often need to quickly solve technical problems and optimize design solutions during the design process. Johoty company provides professional technical support, and Johoty’s CFT team can respond promptly to the selection and design suggestions of pogo pin connectors in the early stage, as well as the resolution of application problems in the later stage. We always align with our client to ensure their project progress is not affected.

Johoty usually uses FedEx, DHL, UPS, TNT deliver goods to customers in a timely manner, and we have sent them to Italy within 3 days at the fastest. We always use WhatsApp, Skype, WeChat, Phone, and email provide quick response and timely support to our customers. Customers can receive timely response and technical support from us, solve problems without delay, and ensure that the product always operates efficiently.

Conclusion: Future Trends in IP68 Waterproof

With development of IoT, automation, and smart devices, IP68 waterproof pogo pin connector is increasingly using in high demand applications. In the future, IP68 waterproof will be increasingly used in consumer electronics, industrial equipment, automotive electronics, and smart wearable devices. To meet higher durability and reliability, IP68 pogo pin connector will be developed towards miniaturization, high sealing, and adaptability to extreme environments.

In this trend, Johoty’s pogo pin connector excellent sealing performance, reliable electrical contact, and durability can provide you with an ideal solution. For consumer electronics for precise protection and smart devices in complex industries, Johoty’s IP68 pogo pin connector ensures device stability.

Choosing Johoty’s IP68 pogo pin connector is a more efficient, safe, cost-effective, reliable solution. Contact Johoty immediately to learn more and ensure your project has the strongest connection guarantee.