What is Magnetic Force and its impact on the magnetic connector? Detailed insights into how magnetic force influences connector performance

1. Introduction

Magnet force is amazing, it is not just everywhere in our daily lives but also crucial in technology innovation. Magnetic connector, one of its key applications, is not only fascinating but deeply influence modern tech development.

This article dives into the nature of magnetic force, its impact on magnetic connector, and reveals their importance and future applications in technology. As we explore together, you’ll discover the mysterious allure of magnetic force and its endless possibilities in tech innovation.

2. Basics of Magnetic Force

2.1 Definition and Basic Characteristics of magnetic force

Magnetism Neodymium magnets, like those in magnetic connectors, have strong magnetic properties and excellent stability. Their magnetic force is their ability to attract and repel other objects, stemming from strong magnetic domains in their microstructure. Key characteristics of neodymium magnets include:

- High magnetic energy product: Neodymium magnets have the highest magnetic energy among commercial magnets, giving them a significant edge in compact devices and high-performance applications.

- Strong magnetic field: They generate a powerful magnetic field, allowing quick, stable adhesion in magnetic connector while maintaining durability.

- Stability and corrosion resistance: These magnets have good chemical stability and corrosion resistance, suitable for diverse environments like humidity, high temperatures, and chemical exposure.

- Magnetic orientation: Neodymium magnets are isotropic, meaning they exhibit similar magnetic properties in all directions, crucial for design and application convenience.

- Temperature characteristics: Despite their excellent magnetic force, their strength can weaken with temperature changes, particularly under high heat.

Neodymium magnets, as core components of magnetic connector, support modern tech applications with their high energy, strong fields, stability, and corrosion resistance. They’re widely used in electronics, medical devices, automotive industries, and are integral to modern tech advancement.

2.2 Generating Magnetic Fields and Properties of Magnetic Poles

Neodymium magnets are robust permanent magnets commonly used in magnetic connector. They’re composed of neodymium (Nd), iron (Fe), and boron (B), boasting high magnetic energy and effective magnetization:

2.2.1 Mechanism of magnetic field generation:

- Neodymium magnets’ magnetic field primarily arises from their crystal lattice structure and microscopic magnetic domains.

- In these magnets, the arrangement of neodymium and iron forms a strong magnetic lattice, enhancing their magnetic energy and output.

- During manufacturing, magnets undergo magnetization processes involving annealing and rapid cooling in magnetic fields, aligning their microscopic magnetic domains in a fixed direction to produce a robust magnetic field.

2.2.2 Properties of magnetic poles:

- Neodymium magnets typically have two poles: north and south.

- The positioning and characteristics of these poles depend on the magnetization direction during manufacturing.

- In magnetic connector, these pole configurations affect adhesion strength and stability.

- Pole properties include magnetization direction, magnetic field strength, and uniformity, directly influencing the performance and reliability of magnetic connector.

Due to their superior magnetic properties, neodymium magnets find extensive use in modern technologies, especially in applications requiring strong magnetic fields and stability.

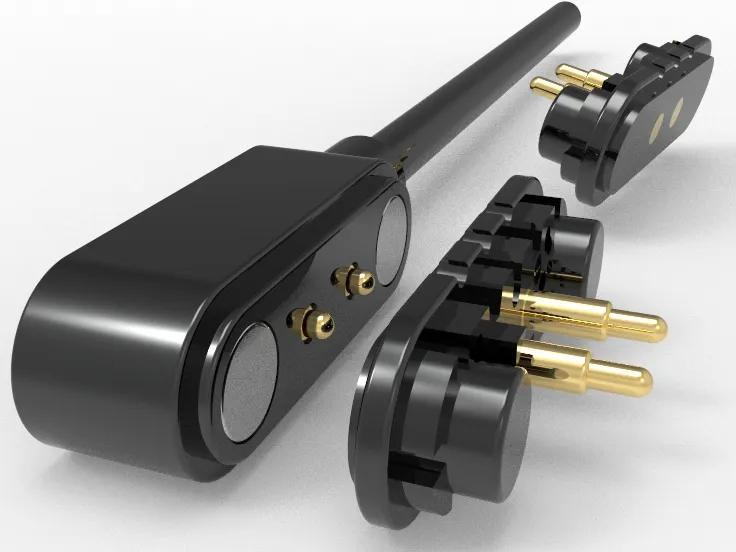

3. How Magnetic Connector Works?

3.1 The magnetic connector uses magnets to attach and detach. Here’s how it works:

3.1.1 Choosing Magnetic Materials:

- Magnetic connector typically uses permanent materials like neodymium magnets or ceramic magnets. These materials have stable magnetic properties and high magnetic energy, generating strong magnetic fields.

3.1.2 Generating Magnetic Fields:

- Inside the magnetic connector, magnets are magnetized to create two poles: north and south.

- When the connectors approach each other, the magnetic fields interact with the magnetic materials, creating attraction that quickly pulls them together.

3.1.3 Connecting Process:

- As they come close, the magnetic poles attract, pulling the connector parts together rapidly.

- When they reach a certain distance, the magnetic force aligns and connects them almost automatically, without needing manual intervention.

3.1.4 Disconnecting Process:

- To disconnect, you apply a separating force to overcome the magnetic attraction.

- Since magnets automatically attract when close, separating them requires just enough force without additional complexity.

3.1.5 Stability and Reliability:

- The stability of magnetic connector depends on the chosen magnetic materials and precision in design.

- Accurate magnet positioning and appropriate magnetic field strength ensure stable connections in various working conditions.

Magnetic connector automates connection and disconnection using powerful magnetic fields from permanent magnets, enhancing operational efficiency and convenience. It is widely used in electronics and industrial applications.

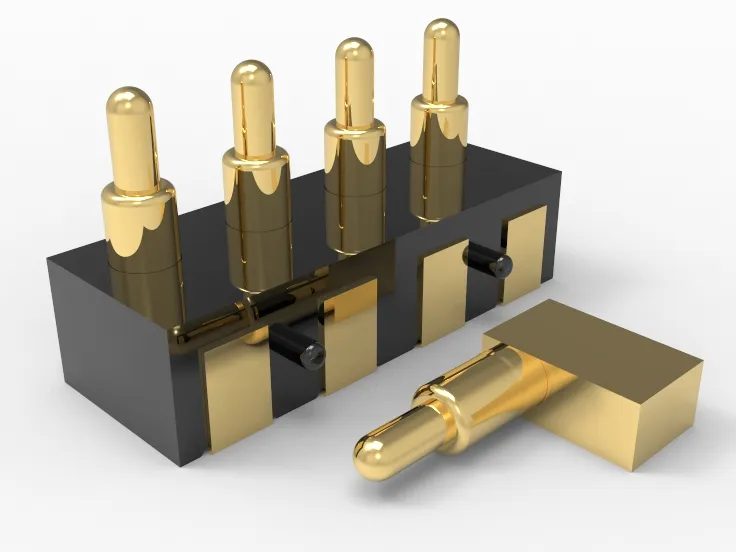

3.2 Comparing and Applications of Different Types of Magnetic Connectors

Magnetic connector is categorized based on magnetic attraction and repulsion into three types: magnetic attraction connectors, magnetic guiding connectors, and magnetic orienting connectors.

- Magnetic Attraction Connectors: These use magnetic attraction to automatically align and connect both ends of the connector. They’re common in consumer electronics like chargers, smartphones, and tablets for quick, convenient connections.

- Magnetic Guiding Connectors: These use magnetic fields for precise alignment, crucial in industrial equipment needing accurate positioning and reliable connections, such as medical devices and automotive electronics.

- Magnetic Orienting Connectors: Combining magnetic attraction with mechanical guidance, these provide strong connection force and ensure correct alignment. They’re found in high-speed data and signal transmission devices like networking and computer peripherals.

- When comparing different types of magnetic connectors, key factors to consider include connection strength, precision, durability, environmental adaptability (e.g., waterproof, dustproof), and electromagnetic compatibility. Each type has unique advantages and is chosen based on specific application needs.

4. Advantages and Disadvantages of Magnetic Connector

Magnetic connector, as a special connection technology, have unique advantages and some potential drawbacks:

4.1 Advantages:

- Quick Connection and Disconnection: Magnetic connector uses magnetic force to automatically align and connect when brought close together, saving time and increasing efficiency without manual operation.

- Ease of Use: Users simply bring devices near the connector, and the magnetic attraction automatically connects, making it very convenient for frequent connections and disconnections.

- Precise Positioning: Some magnetic connectors are designed for precise guiding and alignment, ensuring devices are always in the correct position during connection, which protects device interfaces and extends lifespan.

- Waterproof and Dustproof: Typically designed to be sealed, magnetic connector enhances durability and reliability by resisting water and dust exposure.

- No Mechanical Wear: Unlike traditional connectors, magnetic connectors have no contact point friction, avoiding performance degradation or failure due to wear.

- Design Flexibility: Magnetic connector can be designed in various shapes and sizes to fit different device needs and easily integrate into existing designs, enhancing product flexibility.

4.2 Disadvantages:

- Lower Connection Strength Compared to Mechanical Connectors: Some applications may require stronger connection forces, which is a potential drawback of magnetic connector, especially in vibrating or high-pressure environments.

- Potential Electromagnetic Interference: The magnetic fields generated by magnetic connector may interfere with surrounding electronic devices, requiring appropriate shielding and handling during design.

- Higher Cost: Magnetic connector typically incurs higher manufacturing costs compared to regular mechanical connectors, especially for high-precision and special designs.

- Environmental Sensitivity: Extreme temperatures and chemical environments can affect the performance and stability of magnetic connector, necessitating additional protective measures for reliability.

- Dependency on Magnetic Force: The effectiveness and reliability of magnetic connector can be influenced by specific environmental conditions or materials, limiting their use in certain applications.

Magnetic connector excels in quick connection, ease of use, and design flexibility, but considerations such as connection strength, electromagnetic interference, and cost should be balanced against specific application needs and environmental conditions during selection and design.

5. The Impact of Magnetic Force on Technology Products

5.1 The Influence of Magnetic Connector on Device Design and User Experience

- Magnetic connector, as an innovative connection technology, plays a crucial role in device design. It replaces traditional mechanical connections with magnetic attraction, providing a more convenient and rapid way to connect devices. This design speeds up assembly and cuts down on mistakes and damage. Additionally, magnetic connector is often intricately designed for high integration in compact spaces, optimizing overall device design.

- In terms of user experience, magnetic connector offers significant convenience and safety. Users can quickly connect and disconnect device parts without tools or extra steps. This simplified operation not only saves users time but also reduces operational difficulties, especially when parts need frequent replacement or maintenance. Moreover, designed for plug-and-play functionality, magnetic connector undergoes rigorous testing for durability and stability, ensuring long-term reliability and safety during use.

- As a critical component of modern device design, magnetic connector not only enhance assembly efficiency and design optimization but also greatly improve user operational experience and safety. These advantages make magnetic connector widely popular across various industries and applications, becoming key technologies in many innovative products.

5.2 How Magnetic Force Enhances Product Reliability and User Convenience

- Magnetic force, as a novel connection and fixation technology, plays a significant role in improving the reliability and user convenience of technology products. Firstly, through its powerful magnetic attraction, magnetic connector securely and safely fix device parts during connection, minimizing the risk of loosening or disconnection caused by external vibrations or impacts compared to traditional mechanical connections. This enhances the overall product reliability.

- Secondly, the design of magnetic connector streamlines the assembly and maintenance processes of devices. Users can easily install and replace parts through simple docking or separation actions, without requiring complex tools or specialized skills. This operational method not only reduces the workload of maintenance personnel but also significantly enhances maintenance efficiency and response speed. Especially in scenarios requiring quick part replacement or upgrades, magnetic connector substantially reduces operation and production downtime, thereby boosting production efficiency and user satisfaction.

- Additionally, designed as contactless plug-and-play, magnetic connector avoids electrical connection issues due to poor plug contact or oxidation. This design not only improves device stability and durability but also reduces electrical faults and maintenance costs, extending the equipment’s lifespan.

Magnetic force, as a key technology in technology products, significantly enhances connection stability, simplifies operation processes, and reduces maintenance costs, thereby improving product reliability and user experience. These advantages make magnetic connection technology widely applicable across multiple industries and scenarios, enhancing product competitiveness and user satisfaction.

Conclusion

Magnetic force is a fundamental physical force that attracts objects without direct contact. Magnetic connector utilizes this force to achieve rapid device connection and reliable data and power transmission functionalities. Understanding and leveraging the advantages of magnetic force not only enhances device efficiency and reliability but also opens up broader opportunities for technological innovation.

Through in-depth research and application of magnetic technology, we can drive future connector design development, realizing safer and smarter device interconnectivity. For inquiries about various high-end magnetic connector, please contact Johoty.