What is PEEK? Johoty Employs PEEK to Ensure Pogo Pin Connector Endures Temperatures Up to 150℃, Perfect for Client Demanding Heat Applications

Introduction:

- What is Peek? Peek is a super-tough plastic that can handle extreme temperatures and resist chemicals, making it perfect for demanding engineering tasks. It stays reliable even at temperatures as high as 150°C, so it’s perfect for tough conditions. PEEK’s top-notch performance has made it popular in fields like electronics, aerospace, cars, and healthcare.

- In demanding thermal applications, traditional materials often fall short in meeting the requirements for high temperatures, high pressures, or chemical corrosion. Because PEEK can withstand high temperatures and is incredibly strong, it’s the perfect material for these applications.

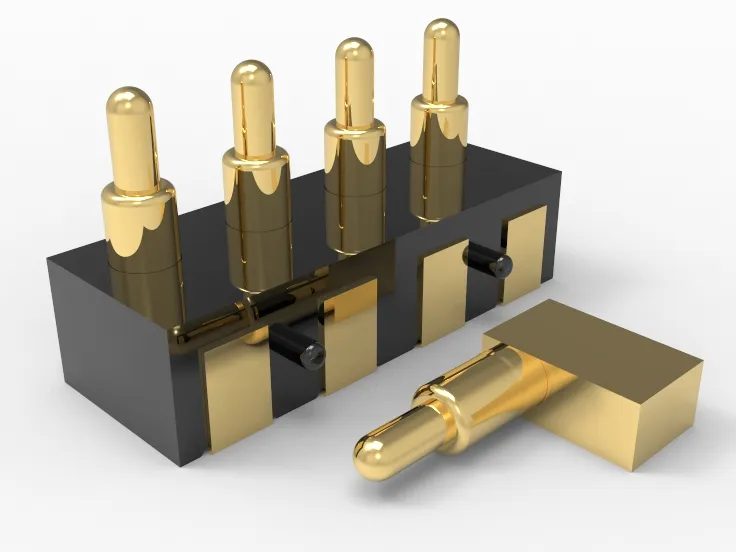

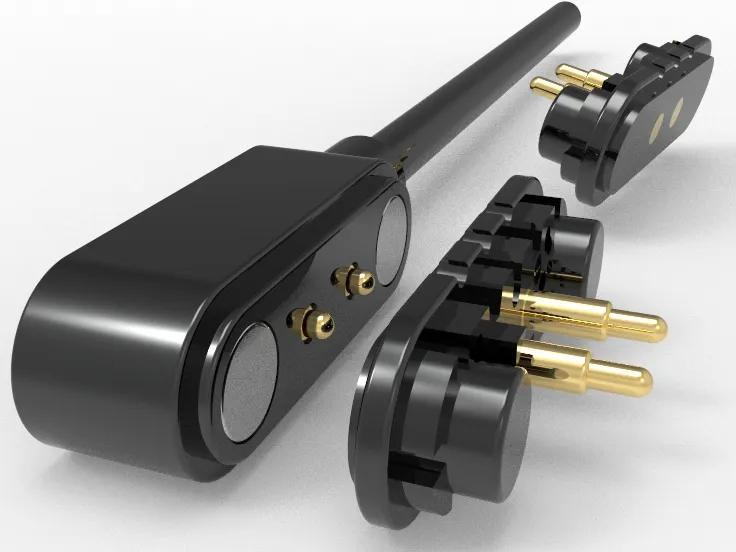

- For instance, in Johoty’s Pogo Pin Connector, PEEK ensures that the connector operates reliably at temperatures up to 150°C, meeting the customer’s need for reliability in harsh conditions. Its superior heat resistance and long-term stability make PEEK a key material in overcoming the challenges of high-temperature applications.

What is PEEK? PEEK Characteristics:

1. What is PEEK? Its High-Temperature Resistance:

- High Melting Point: PEEK has an exceptionally high melting point, usually above 343°C (650°F). This allows it to maintain stable physical and chemical properties in high-temperature environments, making it suitable for extreme conditions.

- Excellent Thermal Stability: PEEK does not easily decompose or degrade at high temperatures, enduring continuous use at temperatures up to 250°C (482°F) without performance degradation.

- Superior Heat Deflection Temperature: PEEK’s heat deflection temperature reaches about 160°C (320°F), maintaining its shape and size stability at this temperature.

- Good Thermal Conductivity: PEEK has relatively high thermal conductivity, helping to effectively dissipate heat in high-temperature applications and preventing performance issues caused by heat accumulation.

- Heat Aging Resistance: Even with long-term exposure to high temperatures, PEEK retains its mechanical properties and electrical insulation characteristics, demonstrating excellent resistance to heat aging.

- Low Water Absorption: PEEK has very low water absorption, keeping its physical properties stable.

In Johoty’s Pogo Pin Connector, PEEK demonstrates excellent high-temperature resistance, allowing reliable performance even in extreme conditions and ensuring long-term stability and performance.

2. What is PEEK? Its Mechanical Strength:

In Johoty’s Pogo Pin Connector, PEEK is chosen for its renowned mechanical properties. Its unique advantages make it unparalleled in connector applications:

- Exceptional Wear Resistance: PEEK is highly wear-resistant, maintaining connector longevity and stability even with frequent insertion and removal. It effectively reduces wear and failure risks, ensuring a reliable electrical connection.

- High Tensile Strength: PEEK can withstand heavy loads without deforming or breaking, ensuring connector stability and durability under high-stress conditions.

- Excellent Chemical Resistance: PEEK resists various chemicals, including acids, bases, and solvents, maintaining performance and reliability even in harsh environments.

- Stable High-Temperature Performance: PEEK’s thermal stability allows it to perform well at temperatures up to 250°C without losing its mechanical strength or physical properties. This ensures the connector works normally in high-temperature conditions without being affected by thermal expansion and contraction.

- Low Friction Coefficient: PEEK has a low friction level, which means it helps connectors slide more smoothly and resist less. This not only makes the insertion and removal smoother but also minimizes heat generated by friction, extending the connector’s lifespan.

- Excellent Electrical Insulation: As an electrical insulator, PEEK effectively prevents current leakage, ensuring the connector’s safety and stability in various electrical environments.

Using Johoty’s Pogo Pin Connector made with PEEK enhances the overall performance of the product, providing customers with higher reliability and a longer lifespan. With Johoty, you experience the perfect blend of high-tech innovation and superior quality.

3. What is PEEK? It’s Chemical Stability:

PEEK stands out in Johoty’s pogo pin connector for its remarkable chemical stability:

- Resistant to Strong Acids and Bases: PEEK maintains its structure and performance in extreme acidic and alkaline environments. It can resist corrosion from strong chemicals like sulfuric acid, hydrochloric acid, hydrofluoric acid, and sodium hydroxide, making it excellent for chemical processing and cleaning.

- Resistant to Organic Solvents: PEEK shows good resistance to a variety of organic solvents, including alcohols, ketones, esters, and chlorinated solvents. This chemical resistance ensures long-term stability in greases, fuels, and other chemical media.

- Resistant to High-Temperature Chemical Reactions: PEEK remains chemically stable at high temperatures, usually up to 300°C, without degradation. This means it can withstand damage from chemical reactions even in high-temperature industrial environments.

- Low Moisture Absorption: PEEK’s low moisture absorption means it resists water and humid environments very well, almost unaffected by moisture. This is crucial for applications requiring stable long-term connections.

- Resistant to Degradation: PEEK materials stay strong and reliable even when they come into contact with different chemicals or face tough environmental conditions. They do not easily degrade or deteriorate, ensuring a long lifespan and reliability for connectors.

These qualities make PEEK perfect for tough jobs, especially where harsh chemicals are involved. Johoty leverages these excellent properties of PEEK to ensure that their pogo pin connector performs exceptionally well under complex working conditions, providing stable and reliable connections.

Johoty’s PEEK Application Cases:

1. Design Requirements:

What is Peek? Its Design:

- High-Temperature Resistance: PEEK material can operate reliably at temperatures up to 250°C. This makes Johoty’s Pogo Pin Connector suitable for high-temperature applications like automotive electronics and aerospace equipment.

- Excellent Mechanical Strength: The high strength and rigidity of PEEK ensure that the Pogo Pin Connector maintains stable electrical connections even under heavy loads and frequent insertions, reducing the risk of poor contact.

- Chemical Stability: PEEK resists most chemicals and solvents, making Johoty’s connectors effective in corrosive environments, ideal for industrial and medical fields.

- Low Electrical Noise: PEEK’s excellent electrical insulation properties help reduce electrical noise and improve signal quality, which is crucial for high-frequency signal transmission and data communication, ensuring connector stability and reliability.

What is PEEK? Its Application Cases:

- Automotive Electronics: In automotive electronic systems, Johoty’s PEEK Pogo Pin Connector is used to link onboard computers and sensors. Their ability to withstand high heat and chemicals guarantees they work well even in tough driving situations.

- Medical Devices: In medical equipment, Johoty’s connectors are used to connect high-precision sensors and control units. The biocompatibility and corrosion resistance of PEEK ensure that these connectors remain stable over long-term use, meeting the medical industry’s high reliability standards.

- Aerospace: In the aerospace sector, Johoty’s PEEK Pogo Pin Connector is employed to link crucial navigation and communication devices. Their high-temperature and impact resistance ensure stable operation in complex flight environments.

Design Challenges and Solutions:

- Stability in High-Temperature Environments: Thanks to PEEK’s high-temperature stability, Johoty had to ensure that all connector components could withstand heat without deforming. By precisely controlling the manufacturing process and material ratios, Johoty successfully overcame this challenge.

- Mechanical Strength and Flexibility: While maintaining high strength, Johoty also needed to ensure the flexibility of the Pogo Pins to allow the connector to return to its original state after frequent insertions and removals. Johoty achieved this by optimizing the design and using high-quality PEEK materials.

2. What is PEEK? Its Thermal Application Requirements:

Extreme Temperature Performance:

Customers have stringent thermal application needs for Pogo Pin Connector, particularly in high-temperature environments. PEEK’s excellent heat resistance makes it an ideal choice, capable of stable operation in environments up to 260°C, ensuring reliable electrical performance under extreme temperatures. This high-temperature stability makes PEEK critical for aerospace, automotive, and other high-temperature applications, meeting demanding customer requirements.

Outstanding Chemical Resistance

- In many industrial applications, Pogo Pin Connector comes into contact with various chemicals like acids, bases, and solvents. PEEK’s excellent chemical resistance allows it to withstand these substances, ensuring the connectors continue to function properly in harsh environments.

- This resistance greatly extends the product’s lifespan and reduces maintenance and replacement costs due to corrosion.

High Strength and Wear Resistance

- Customers demand high mechanical strength and wear resistance from Pogo Pin Connector, especially with frequent plugging and unplugging. PEEK material offers exceptional strength and wear resistance, maintaining stable contact and conductivity through repeated use.

- This ensures long-term reliability, making it suitable for demanding industrial applications.

Superior Electrical Insulation

- Good insulation is crucial for safe and stable electrical connections. PEEK provides excellent electrical insulation, preventing shorts and interference effectively.

- This makes Pogo Pin Connector ideal for applications requiring high electrical insulation, like medical devices and precision instruments, meeting strict safety requirements.

Lightweight Design

- In many applications, especially in portable devices and aerospace, a lightweight design is crucial. PEEK material not only performs exceptionally well but also has a lower density compared to traditional materials, reducing the connector’s weight.

- This lightweight design enhances overall device performance and ease of use, fulfilling the need for lighter components.

What is PEEK? PEEK Technical Details:

1. Manufacturing Process:

What is PEEK? Peek Manufacturing Process:

- High-Temperature Synthesis: The production of PEEK begins with a high-temperature synthesis process. In this step, difluorobenzene and difluoroketone react at high temperatures to create the polymer. This requires precise temperature control to ensure the material’s purity and quality.

- Precision Extrusion: After synthesis, the PEEK resin is fed into an extruder, where it is processed into long strips or sheets. This step makes sure the material is even and steady, preparing it for the next stage of processing.

- Injection Molding: The PEEK material is heated to a molten state and then injected into molds for Pogo Pin Connector. This molding process needs to be highly controlled to ensure that each pin meets the design specifications.

What is PEEK? Technical Requirements and Advantages:

- High Temperature Resistance: PEEK can withstand high temperatures while maintaining stable mechanical properties. This means that Johoty’s Pogo Pin Connector can function reliably in high-temperature environments, ensuring stable connections.

- Excellent Mechanical Strength: PEEK has outstanding mechanical strength and toughness, making it able to handle high pressure and wear. This is crucial for the long-term use and frequent plugging and unplugging of Pogo Pin Connector.

- Chemical Resistance: PEEK can handle a wide range of chemicals without breaking down, staying stable in different chemical settings. This ensures the reliability of the Pogo Pin Connector in harsh conditions.

- High Insulation Performance: PEEK offers superior insulation, effectively preventing electrical leakage and short circuits, ensuring the connector’s electrical performance.

2. What is PEEK? Its Quality Control:

- Material Choice: Johoty uses high-performance PEEK material, known for its excellent heat resistance. PEEK can handle continuous temperatures up to 250°C and even higher temperatures for short periods, ensuring the connector remains stable and functional under extreme conditions.

- Strict Quality Control: Johoty enforces stringent quality control standards during production. Every PEEK pogo pin connector undergoes high-temperature aging tests to confirm its stability and performance in hot environments. These tests help identify potential material defects and production issues, ensuring the final product’s reliability.

- Optimized Design: Johoty has optimized the pogo pin connector design to enhance its heat resistance. This includes improved plating techniques and spring designs to boost conductivity and mechanical strength at high temperatures. The refined design not only increases the connector’s heat resistance but also improves its long-term stability.

- Advanced Manufacturing Processes: Johoty employs cutting-edge manufacturing techniques and equipment to precisely control temperature and pressure during production, ensuring each connector meets high heat resistance standards. By using high-accuracy machining and assembly, we improve the connector’s performance and extend its lifespan.

- Comprehensive Testing: In addition to regular high-temperature tests, Johoty conducts a range of comprehensive tests, including high-temperature humidity tests and thermal cycling tests. These tests simulate various real-world conditions to verify the connector’s stability and reliability in different environments.

Conclusion: What is PEEK?

- PEEK is a top-notch engineering plastic that excels at withstanding heat and chemicals, which makes it a favorite for many users. Johoty uses PEEK to manufacture pogo pin connector because it remains stable at extreme temperatures up to 250°C, which is crucial for heat-resistant applications.

- What is PEEK then? We know PEEK’s thermal stability ensures that the Pogo Pin Connector do not degrade or fail over time, guaranteeing their reliability and performance. Johoty’s selection highlights their focus on quality and their strong awareness of what their customers are looking for.