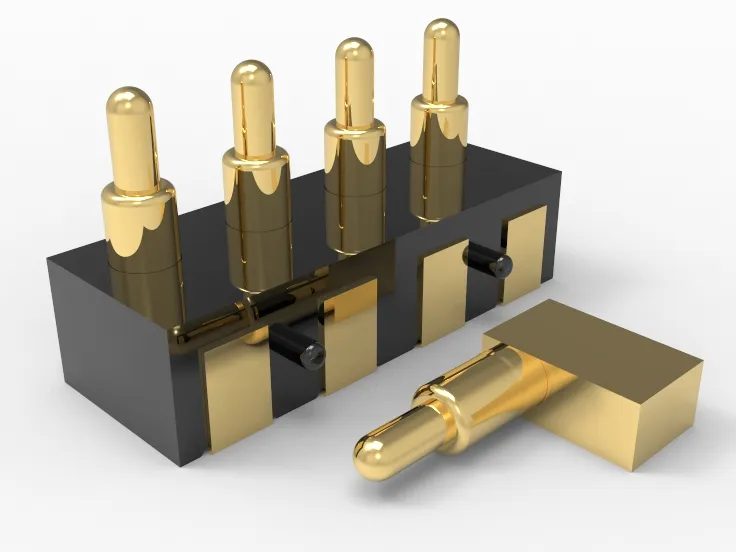

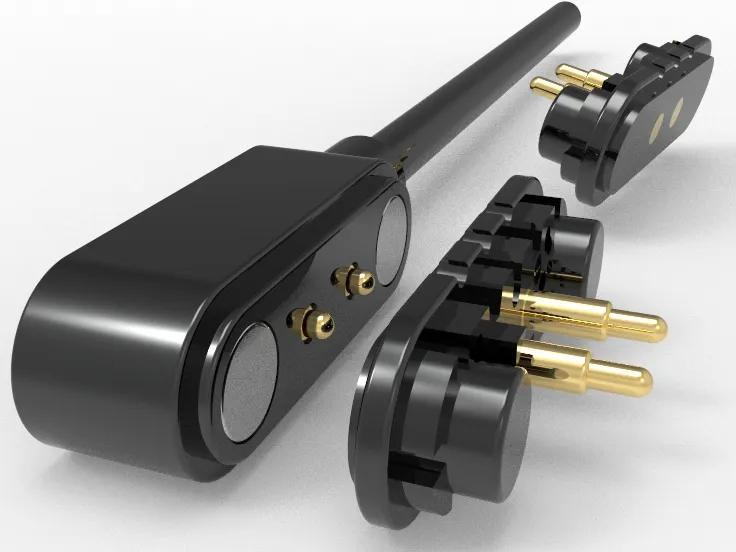

What is performance Testing? Discover How Johoty Ensures Top-quality Pogo Pins with Rigorous Tests Meeting All Quality and Budget Requirements

Introduction

In today’s competitive market, product quality is not only the key to a company’s success but also the foundation for earning customer trust. Making sure products work well and consistently in different situations relies heavily on performance testing. In simple terms, performance testing is about evaluating and optimizing how a system behaves under load to ensure it meets expected performance standards in real-world use.

Performance testing simulates different usage scenarios to measure system response time, stability, and scalability. It goes beyond basic functionality testing, focusing on how the system performs under varying loads. For hardware products like Pogo Pins, performance testing is especially critical. It helps identify how well the product performs in high-frequency use, extreme environments, and more, ensuring long-term reliability and stability.

In this blog, we’ll dive deep into performance testing, exploring how it uses a variety of rigorous methods to ensure product quality. Specifically, we’ll look at how Johoty conducts comprehensive performance testing to ensure its Pogo Pins meet all quality standards while staying within budget. Through an analysis of Johoty’s real-world case studies, you’ll learn how performance testing can optimize product design and enhance customer satisfaction.

Types of Performance Testing

1. Load Testing: What’s Load Testing? What is Performance Testing?

Load testing, as the name suggests, involves applying specific forces or pressures to Pogo Pins to mimic various real-world working conditions. The goal here is to assess how durable, stable, and reliable Pogo Pins are when subjected to high pressure and frequent use. Through load testing, Johoty ensures that their Pogo Pins can withstand long-term use without easily wearing out, while maintaining excellent electrical connection performance.

Key Aspects of Load Testing:

- Static Load Testing: This involves applying a constant pressure to Pogo Pins and continuously monitoring their electrical performance and physical structure. The aim is to make sure that over prolonged use, the pins don’t become loose or develop poor connections.

- Dynamic Load Testing: Here, we simulate the actual usage scenarios where Pogo Pins undergo repeated plugging and unplugging, vibrations, and shocks. This helps evaluate how well they perform in more complex environments.

- Temperature and Humidity Load Testing: Pogo Pins are tested under extreme temperature and humidity conditions to ensure they maintain top-notch performance across various climates.

- Fatigue Load Testing: By repeatedly applying pressure, we test the durability of Pogo Pins after multiple uses, ensuring they have a long-lasting and reliable lifespan.

2. Stress Testing: What’s Stress Testing? What is Performance Testing?

Stress testing, also known as extreme condition testing, involves pushing Pogo Pins beyond their normal operating limits by applying extreme pressures or loads. This type of testing aims to uncover any weaknesses that might emerge under harsh conditions like high pressure, high temperatures, or intense vibrations. The objective is to ensure that Pogo Pins can operate smoothly in real-world applications without being affected by environmental changes.

Core Elements of Stress Testing:

- Applying Extreme Pressure: Pogo Pins are subjected to pressures beyond their rated working limits to simulate extreme usage environments. This tests their ability to withstand stress and maintain structural integrity.

- High-Temperature and High-Pressure Cycling: By alternating between high temperatures and pressures, we assess the stability and reliability of Pogo Pins under frequent temperature shifts and pressure fluctuations.

- Vibration Resistance Testing: Simulating the vibrations that occur during transportation, installation, and use, we ensure that Pogo Pins maintain strong electrical connections and mechanical performance even under vibrational stress.

- Corrosion-Resistant Stress Testing: Pogo Pins are tested in high humidity and corrosive environments to verify their resistance to corrosion, ensuring they remain unaffected in harsh climates.

3. Reliability Testing: What’s Reliability Testing All About?

Reliability testing is all about evaluating how well Pogo Pins maintain their performance and functionality over extended periods of use. By simulating various real-world working conditions, Johoty ensures that their Pogo Pins not only perform excellently initially but also continue to do so over time. This helps prevent issues like poor connections that could lead to equipment failures and reduced performance.

Core Components of Reliability Testing:

- Lifecycle Testing: This involves simulating the number of plug and unplug cycles that Pogo Pins would experience in actual use. The goal is to ensure that even after thousands or tens of thousands of operations, the pins still provide stable electrical connections and mechanical performance.

- Environmental Adaptability Testing: Pogo Pins are tested under extreme temperatures, humidity, dust, and other environmental conditions to ensure they operate reliably in a variety of climates and working environments.

- Vibration and Shock Testing: By simulating the vibrations and shocks that occur during transportation, installation, and use, we evaluate the pins’ resistance to interference, ensuring their connections remain secure and long-lasting.

- Corrosion Resistance Testing: Exposing Pogo Pins to corrosive gases or liquids tests their ability to resist corrosion, ensuring they remain undamaged and maintain excellent electrical performance even in harsh chemical environments.

- Electrical Reliability Testing: This assesses how Pogo Pins perform under high voltage and high current conditions, ensuring their electrical connections are stable and safe, preventing equipment damage due to electrical failures.

4. Response Time Testing: What’s Response Time Testing All About?

Response time testing, also known as reaction speed testing, is a crucial method for evaluating how quickly Pogo Pins can receive and transmit signals. This test measures the delay in the electrical connection process, ensuring that Pogo Pins maintain stable and efficient performance during high-frequency signal transmission and rapid connection operations. Through response time testing, Johoty ensures their Pogo Pins excel in applications that require high-speed data transfer and instant responses, meeting the stringent demands of modern electronic devices for efficient connectivity.

Core Elements of Response Time Testing:

- Signal Delay Measurement: Precisely measuring the time it takes for signals to pass through Pogo Pins ensures they maintain low latency during high-speed data transmission, enhancing the overall response speed of devices.

- High-Frequency Signal Stability Testing: Evaluating how Pogo Pins perform in high-frequency signal environments ensures they maintain excellent connection performance even during frequent switching and heavy workloads.

- Quick Connect and Disconnect Testing: Simulating rapid plugging and unplugging of Pogo Pins assesses their ability to respond swiftly, ensuring reliable electrical connections even during frequent operations.

- Temperature Impact on Response Time Testing: Testing Pogo Pins’ response times under different temperature conditions ensures they can quickly respond in both high and low-temperature environments without being affected by temperature changes.

- Electromagnetic Interference (EMI) Testing: Assessing how Pogo Pins handle response times in environments with electromagnetic interference ensures they can still transmit signals quickly and accurately, even in complex electromagnetic settings.

Johoty’s Performance Testing Methods

1. Using Automated Tools for Testing. What is Automated Tool Testing? What is Performance Testing?

Automated tool testing involves using high-precision automated testing equipment and software to thoroughly evaluate the performance of Pogo Pins, replacing traditional manual testing methods. With these automated tools, Johoty can complete complex testing processes in a very short time, ensuring results are more accurate and faster. Additionally, automated testing can be repeated thousands of times without any deviation. This greatly enhances testing efficiency, ensuring that every batch of Pogo Pins undergoes strict and standardized inspections to guarantee consistent and stable product quality.

Key Steps in Automated Tool Testing

Comprehensive Electrical Performance Testing

- Description: Automated tools precisely measure key electrical performance parameters of Pogo Pins, such as current, voltage, and contact resistance.

- Purpose: Ensures stability and reliability in high voltage and high-frequency environments.

Mechanical Life Testing

- Description: Automated equipment repeatedly inserts and withdraws Pogo Pins and applies pressure tests.

- Purpose: Simulates real-world usage to evaluate mechanical performance and lifespan after multiple operations.

Environmental Adaptability Testing

- Description: Tests Pogo Pins under varying temperatures, humidity, and vibration conditions using automated tools.

- Purpose: Ensures reliable operation even in extreme environments.

Rapid Fault Detection

- Description: Automated tools quickly identify any minor performance anomalies during testing.

- Purpose: Enables quick fixes to make sure products reach top quality before they’re shipped out.

Data Recording and Analysis

- Description: Automated testing tools record and analyze each test result precisely.

- Purpose: Ensures traceability of product parameters and provides data support for further performance optimization.

2. Manual Testing Methods and Steps. What is Manual Testing? What is Performance Testing?

Manual testing involves a comprehensive performance evaluation of Pogo Pins through human operation and observation. This method emphasizes the combination of human effort and expertise, allowing potential issues to be discovered in detail. Ensures every product hits the highest quality marks before they’re dispatched from the factory. Johoty employs manual testing to ensure that its Pogo Pins excel not only in technical specifications but also perform outstandingly in practical applications.

Key Steps in Manual Testing

Visual Inspection

- Visual Examination: Engineers use high-magnification microscopes to thoroughly inspect the appearance of Pogo Pins, ensuring there are no cracks, deformations, oxidation, or other surface defects.

- Dimension Measurement: Precision measuring tools are used to ensure each Pogo Pin meets design specifications, guaranteeing accuracy during the connection process.

Mechanical Performance Testing

- Insert/Withdraw Cycle Testing: Manually inserting and withdrawing Pogo Pins repeatedly simulates real-world usage to evaluate durability and elastic recovery.

- Pressure Testing: Manually applying varying pressures tests the Pogo Pins’ ability to withstand different pressure conditions, ensuring stability in high-pressure environments.

Electrical Performance Testing

- Contact Resistance Measurement: Professional instruments are used to manually measure the contact resistance of Pogo Pins, ensuring low impedance and high conductivity in electrical connections.

- Current Carrying Capacity Testing: Manually applying different currents assesses the stability and safety of Pogo Pins under high current conditions.

Environmental Adaptability Testing

- Temperature Variation Testing: Pogo Pins are placed in different temperature environments, and their performance changes are manually monitored to ensure reliability under both high and low temperatures.

- Humidity Testing: Manually controlling humidity tests the Pogo Pins’ resistance to corrosion and oxidation in moist environments.

Fatigue Testing

- Long-term Use Testing: Prolonged manual insert/withdraw operations simulate long-term use, ensuring excellent durability and stability.

3. Data Collection and Analysis Techniques. What is Data Collection and Analysis Technology? What is Performance Testing?

Collecting and examining data means methodically gathering, sorting, and looking over the large sets of information that Pogo Pins produce in different testing scenarios. This vital technology checks how effectively they work and how reliable they remain. Through these techniques, Johoty can accurately understand how Pogo Pins perform in different environments, identify potential issues, and optimize their design and functionality, ensuring each Pogo Pin excels in real-world applications.

Core Components of Data Collection and Analysis Technology

Real-time Data Collection

- High-Precision Sensors: Sensors installed on testing equipment collect real-time data on performance indicators such as insertion/removal, pressure, current, and voltage, ensuring comprehensive and accurate data.

- Automated Data Recording: Automated systems record the collected data into databases in real-time, ensuring data integrity and traceability.

Big Data Processing

- Data Cleaning and Preprocessing: Raw data is cleaned to remove noise and outliers, ensuring the accuracy of subsequent analyses.

- Data Integration and Storage: Data from different sources is integrated and standardized for easy future analysis and application.

Advanced-Data Analysis

- Statistical Analysis: Statistical methods are applied to describe and infer performance indicators, identifying trends and anomalies.

- Machine Learning, Artificial Intelligence: Using machine learning, we can guess how Pogo Pins perform in different settings, spotting hidden trends and links in the data.

- Multidimensional Cross-analysis: Comprehensive evaluation of Pogo Pins’ performance in various complex environments through multidimensional data cross-analysis.

Visualization and Report Generation

- Dynamic Dashboards: Data visualization tools create dynamic dashboards that display real-time performance data, helping engineers quickly understand test results.

- Detailed Analysis Reports: Comprehensive reports are generated, including key findings, data charts, and optimization recommendations, providing a scientific basis for product improvement.

Johoty’s Performance Testing Use Cases

1. How Does Johoty Implement Rigorous Performance Testing to Ensure the Quality of Pogo Pins? What is Performance Testing?

When smartphone manufacturers are choosing a Pogo Pins supplier, Johoty shines thanks to its stringent performance testing system. Through a series of tough tests, Johoty’s Pogo Pins perform exceptionally well in high-frequency signal transmission and fast charging, significantly boosting the overall performance and user experience of smartphones.

Case Details:

- Client Requirements: The smartphone maker needed Pogo Pins that maintain low latency and high stability during high-frequency signal transmission and fast charging, and that could endure tens of thousands of insertion and withdrawal cycles.

- Johoty’s Solution: Johoty delivered a range of Pogo Pins that underwent rigorous load, pressure, and lifecycle testing. By using automated tools for real-time monitoring and data analysis, Johoty ensured each Pogo Pin met the client’s high standards.

- Test Results: Johoty’s Pogo Pins kept low latency in high-frequency signal transmission, showed no performance drop during fast charging, and successfully passed tens of thousands of insertion and withdrawal cycles, demonstrating outstanding reliability.

- Client Feedback: The smartphone manufacturer highly praised Johoty’s product quality and meticulous testing processes, deciding to partner with Johoty long-term to further enhance their product’s market competitiveness.

2. How Does Johoty Meet Customer Quality and Budget Requirements Through These Tests? What is Performance Testing?

Johoty is dedicated not only to providing top-quality Pogo Pins but also to optimizing testing processes and manufacturing techniques. This way lets customers save money without cutting corners on quality, ensuring they get their money’s worth.

Efficient Production and Testing Processes:

- Combining Automated and Manual Testing: Johoty uses automated testing for critical steps to boost efficiency while incorporating manual testing to ensure every detail is perfect, reducing unnecessary rework and waste.

- Batch Production Optimization: Through precise data analysis, Johoty optimizes production batches, minimizes material waste, and shortens production cycles, lowering overall costs.

Intelligent Data Analysis:

- Predictive Maintenance: Leveraging machine learning and artificial intelligence, Johoty predicts how Pogo Pins will perform under various conditions, allowing for proactive maintenance and optimization, which reduces failure rates and maintenance costs.

- Design Optimization: Data-driven design improvements enhance the performance and durability of Pogo Pins, extending their lifespan and lowering long-term usage costs.

Supply Chain Management:

- Cost Control: With meticulous supply chain management, Johoty optimizes raw material procurement and inventory management, reducing production costs.

- Flexible Customization Services: Johoty offers customized Pogo Pin solutions tailored to specific customer needs, avoiding resource waste and enabling cost-effective, tailored solutions.

Conclusion

Through a comprehensive performance testing system and advanced data collection and analysis technologies, Johoty not only ensures the exceptional quality of its Pogo Pins but also strikes the perfect balance between quality and budget by optimizing testing processes and manufacturing techniques.

Choosing Johoty means opting for high-performance, cost-effective Pogo Pin products that help your electronic devices stand out in a competitive market, earning customer trust and satisfaction.