What is Process Control? Explore How Johoty’s Approach Guarantees Precise Pogo Pins with Minimal Costs for Rigorous Accuracy and Budget Demands

Introduction: What is Process Control?

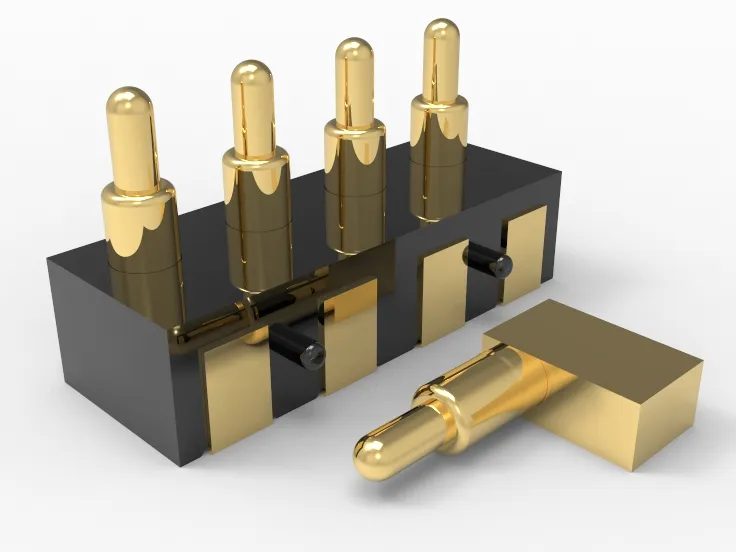

- In industrial production, process control is at the heart of ensuring product quality and production efficiency. Particularly in the manufacturing of high-precision Pogo Pins, precise process control not only reduces costs but also meets clients’ stringent demands for accuracy and budget. As a leading manufacturer of high-precision Pogo Pins, Johoty achieves the perfect balance between efficient production and cost optimization through advanced process control technologies.

- Process control involves every stage, from raw material selection, production processes, equipment maintenance, to quality inspection. Johoty applies a range of efficient methods at each stage, including automated production lines, real-time data monitoring, and a strict quality management system. These meticulous management approaches enable Johoty to maintain high product precision while minimizing production costs, ensuring every Pogo Pin meets the highest quality standards.

- In this blog, we will explore the fundamental concepts of process control, how Johoty leverages these methods for efficient production, and analyze how these technologies help us meet customer demands while keeping costs to a minimum. Whether you’re interested in technical details or practical applications, we’ll showcase Johoty’s innovations and practices in process control.

Basic Concepts of Process Control

1. Definition of Process Control: What is Process Control?

Process control is a key technology in managing and optimizing the production and service processes of Pogo Pins, ensuring that each stage operates efficiently and accurately according to set standards and requirements. It involves monitoring, adjusting, and optimizing various production phases to achieve the desired quality, efficiency, and cost goals. Through refined control strategies, companies can guarantee Pogo Pin quality, meet customer needs, reduce production costs, and increase efficiency.

Key Concepts: What is Process Control?

- Process Monitoring: This is the core of process control, involving real-time tracking of various parameters in the production process. By using sensors and data collection systems, we can quickly gather production data and react promptly to any potential deviations.

- Process Adjustment: During monitoring, the system automatically adjusts parameters based on set standards. For example, machine speed, temperature, or other operational conditions can be adjusted to keep the production process running in optimal condition.

- Data Analysis: Analyzing our production data helps us find any roadblocks or trouble spots in the workflow. These insights from the data help us fine-tune our production, cut down on failures, and boost the quality of our products.

- Automation: Automation systems (like PLC and DCS) are widely used. These systems execute preset control strategies automatically, minimizing human intervention and improving production stability and consistency.

- Feedback Mechanism: Effective process control relies not only on real-time data and automatic adjustments but also on feedback mechanisms. By analyzing production outcomes, we can further fine-tune control strategies to optimize the process.

2. Key Elements: What is Process Control?

At Johoty, we ensure that our high-precision Pogo Pins meet strict accuracy and budget requirements at the lowest cost through precise process control methods:

- Standardized Processes: The first step in process control is standardizing the production process. This includes detailed operating procedures, standardized workflows, and systematic inspection processes. Standardization helps reduce human error and process variability.

- Real-Time Monitoring: Real-time tracking is essential for maintaining control over our processes. With advanced sensors and data collection systems, we track parameters like temperature, pressure, and speed in real-time. These real-time insights allow us to quickly detect anomalies and make timely adjustments to prevent quality issues.

- Quality Management System: The quality management system plays a critical role in process control. Johoty sticks to ISO 9001 to make sure every stage of production meets high-quality standards. Systematic quality reviews and control measures guarantee that every batch of Pogo Pins meets high precision requirements.

- Data Analysis and Feedback: Data analysis is key to improving process control efficiency. By diving deep into our production data, we uncover potential problems and areas where we can improve. Johoty uses this feedback to continuously improve production processes, optimize resource allocation, reduce costs, and enhance product precision and consistency.

- Employee Training and Management: Effective process control also depends on the skills and qualities of employees. Johoty emphasizes employee training and management to ensure every team member can perform standardized operations and handle unexpected situations. Through regular training and evaluations, we maintain a highly efficient team, ensuring maximum performance during production.

3. Objective: What is Process Control?

Process control is a critical component of industrial manufacturing and management, designed to ensure production stability and consistency through scientific methods. This leads to improved product quality and production efficiency:

Optimizing Resource Utilization

- Process control ensures that every resource, including raw materials, equipment, and labor, is used efficiently through careful monitoring and adjustments, reducing waste and improving resource efficiency.

Maintaining Product Consistency

- In large-scale production, maintaining consistent product quality is essential. Process control uses standardized production methods and real-time feedback systems to ensure that every Pogo Pin meets set size, performance, and reliability standards, avoiding quality issues caused by production fluctuations.

Reducing Production Costs

- By optimizing the production process, process control effectively reduces extra costs associated with defective products or rework. It also minimizes raw material procurement and inventory costs through accurate demand forecasting and inventory management, leading to cost savings.

Increasing Production Flexibility

- Process control enables quick responses to market changes, adjusting production parameters and configurations to adapt to different specifications and production needs. This keeps the production line adaptable and boosts our edge in the market.

Enhancing Customer Satisfaction

- Stable production processes and consistent product quality directly impact customer satisfaction. Through strict process control, Johoty ensures that every Pogo Pin meets customers’ high-precision requirements, increasing customer satisfaction with the product and service.

Driving Continuous Improvement

- Process control isn’t just about keeping things running smoothly; it’s also about pushing for top-notch performance. With continuous monitoring and data analysis, Johoty identifies improvement opportunities, boosting production efficiency and product quality while fostering innovation and process optimization.

Johoty’s Approach to Process Control

As a leading manufacturer of Pogo Pins, Johoty employs a range of efficient process control methods to meet customers’ strict accuracy and budget requirements:

Precise Design

- Johoty’s precision design is the foundation of our process control. Using CAD and advanced engineering simulation technologies, we ensure that every Pogo Pin design meets the highest standards.

- Our design team leverages state-of-the-art modeling tools to perform detailed performance analyses and optimizations, ensuring every design detail meets clients’ accuracy needs.

- This approach minimizes design errors, streamlines production processes, and reduces production costs.

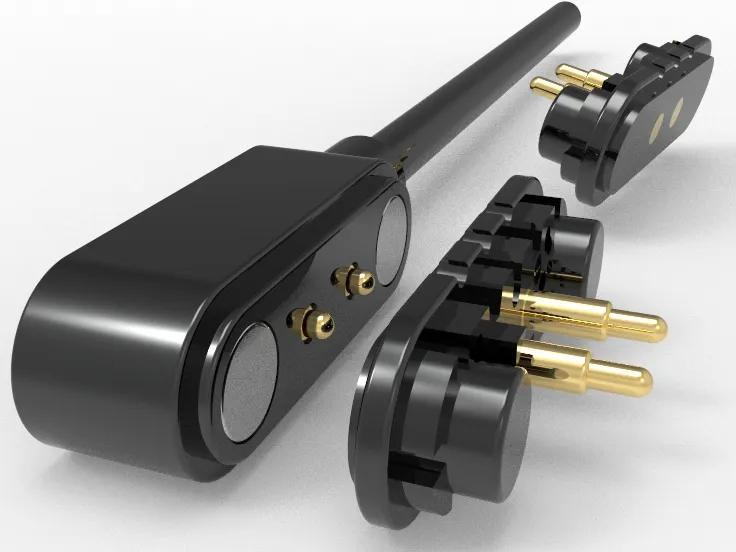

Automation Technology

- For Johoty, automation is central to how we control and optimize our processes. We use advanced automated machines and robots in our production lines to increase efficiency and cut down on mistakes.

- Automation allows us to maintain consistent high quality in mass production while lowering labor and time costs.

- These systems also collect real-time data, providing precise feedback at every step of production.

Real-Time Monitoring

- Real-time monitoring is a vital method Johoty employs to maintain high standards of product quality.

- We equip our production lines with advanced sensors and monitoring devices that track key parameters like temperature, pressure, and material flow in real time during Pogo Pin production.

- These data allow us to quickly identify and correct any deviations in the process, ensuring that each batch meets strict quality standards.

- With real-time data analysis, we can swiftly address any issues, ensuring process stability and reliability.

Quality Assurance

- Johoty’s quality assurance system spans the entire production process. From sourcing raw materials to each step on the production line, we strictly follow international standards for quality control.

- Our quality management team conducts thorough inspections and verifications for every batch of Pogo Pins, ensuring they meet clients’ precision and performance requirements.

- We utilize advanced testing equipment, like coordinate measuring machines (CMM) and high-precision spectrometers, to guarantee that each Pogo Pin achieves the highest industry standards.

Through precise design, automation, real-time monitoring, and stringent quality assurance, Johoty is able to produce highly accurate Pogo Pins at the lowest possible cost, meeting various customer precision and budget needs. These smart process control techniques boost production efficiency and guarantee top-quality products every single time.

Johoty’s Cost Control Strategies

Johoty uses a series of effective cost control strategies to ensure that while meeting customers’ stringent precision requirements, we also minimize production costs to the fullest:

Material Selection

- Johoty insists on using top-quality materials in the industry. By establishing strong partnerships with leading global raw material suppliers, we secure the most cost-effective materials.

- This helps cut production costs while also guaranteeing the quality and consistency of our Pogo Pins.

- Johoty rigorously selects and tests all materials, ensuring each batch is of the highest quality, which reduces production losses and quality risks caused by material issues.

Process Optimization

- Johoty continuously optimizes production processes to create more efficient workflows. By introducing advanced production technologies and automation, we streamline manufacturing steps and shorten production cycles.

- Process optimization improves efficiency, reduces human error, and ensures the high precision of Pogo Pins.

- Our engineering team regularly evaluates and improves processes to meet changing market demands, further reducing costs while maintaining product quality.

Investment in Equipment

- Johoty is dedicated to putting money into the latest and greatest production technology. These machines are highly efficient and stable, producing high-precision Pogo Pins in less time.

- By investing in smart equipment, Johoty improves production efficiency and reduces equipment maintenance and downtime, which helps lower production costs.

- We also constantly monitor and evaluate equipment performance to ensure it operates at peak efficiency, further enhancing precision and consistency.

Through these efficient cost control strategies, Johoty delivers high-precision Pogo Pins at the lowest cost, meeting customers’ strict requirements. Our plan is to keep fine-tuning these methods to maintain our top position in the field.

Case Studies

Precision Challenges in the Consumer Electronics Industry

- Client Need: A leading consumer electronics company required high-precision Pogo Pins to ensure stability in frequent plug-and-play operations. They demanded a tolerance of no more than 0.01mm within a tight budget.

- Challenge: The complex working environment of consumer electronics required ultra-high stability and durability for Pogo Pins. Traditional manufacturing methods struggled to maintain precision while controlling costs.

- Solution: Johoty implemented advanced process control techniques, including precise temperature control systems and automated inspection equipment, to ensure each Pogo Pin stayed within the required tolerance. By optimizing production layout and incorporating real-time data monitoring, Johoty achieved an efficient production flow and quality assurance.

- Result: The delivered Pogo Pins met the client’s precision requirements while reducing production costs by 20%. The client was highly satisfied with the long-term stability and cost-effectiveness of the Pogo Pins, strengthening the partnership.

High Standards in the Medical Devices Sector

- Client Need: A medical device manufacturer needed custom Pogo Pins for precision medical instruments, requiring Pogo Pins to withstand up to 10,000 plug-in tests and meet strict biocompatibility standards.

- Challenge: Medical devices demand extreme stability and reliability, and even minor defects could compromise performance and safety. Achieving high precision while meeting biocompatibility standards was the main challenge.

- Solution: Johoty implemented a comprehensive process control system, including high-precision metalworking and strict quality inspection procedures. By using advanced materials and precision manufacturing techniques, each batch of Pogo Pins was thoroughly tested to meet medical industry standards.

- Result: The Pogo Pins excelled in all tests, exceeding the client’s expectations. Their reliability and compliance with biocompatibility standards earned high praise, establishing a foundation for long-term collaboration.

Efficiency Demands in Automotive Electronics

- Client Need: An automotive electronics company required large quantities of high-precision Pogo Pins for their in-car entertainment systems. The client wanted consistent quality in mass production, all within a set budget.

- Challenge: Automotive electronics need to withstand tough conditions like extreme heat and humidity.. Consistency in production and cost control were key concerns.

- Solution: Johoty implemented a precise process control system, incorporating automated production equipment and an efficient quality management system. By optimizing production techniques and introducing advanced inspection technologies, Johoty maintained high precision while effectively controlling production costs.

- Result: The final Pogo Pins met the high standards required for automotive electronics and saved 15% in production costs. The client expressed great satisfaction with Johoty’s solution, leading to deeper and broader cooperation.

Conclusion

At Johoty, we understand the critical role process control plays in Pogo Pin manufacturing. By incorporating industry-leading automated production lines and precision quality monitoring systems, we ensure strict control from raw materials to Pogo Pin delivery, guaranteeing that every batch meets the highest precision standards.

Our process optimizations not only shorten production cycles but also significantly reduce manufacturing costs, helping control customer budgets while ensuring quality. Whether for small-scale custom orders or large-scale production, Johoty is always customer-centric, committed to providing high-precision, efficient, and cost-effective solutions.