What Is Spring Force? Discover its Crucial Impact on Pogo Pin Performance and How Understanding it Can Enhance Your Designs and Products

1. Introduction:

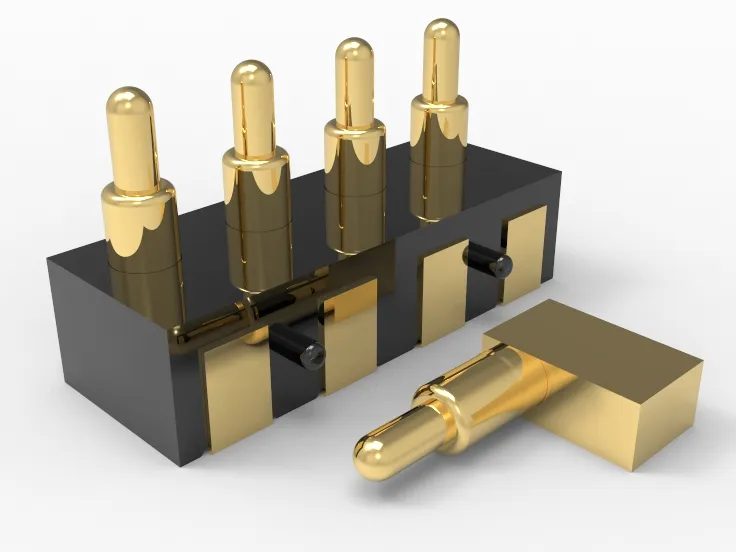

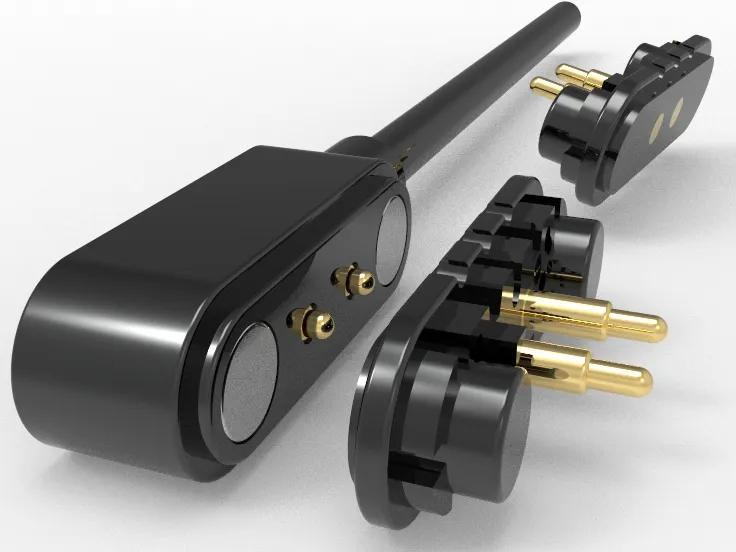

Why is spring force crucial for the performance of Pogo Pins? In modern electronic connector designs, Pogo Pins play a critical role. They’re not just connectors, they ensure devices operate smoothly. The spring’s force is vital for smooth operation. Could you break down what spring force is and why it’s crucial for pogo pin performance?

In mobile devices, comms gear, and electronics, pogo pins are a popular way to make electrical connections. The force behind them isn’t just a physical concept, it’s key to device stability and reliability. This article delves into defining spring force, its principles, and practical applications for optimizing spring pin performance, uncovering the technological secrets behind spring force.

2. Basic Concept of Spring Force:

Spring force is the pushback a spring gives when you stretch or squeeze it. When stretched or compressed, a spring generates a force that restores its shape—this is spring force. Its magnitude depends on the spring’s material and geometry, typically following Hooke’s Law, where spring force is proportional to deformation. In engineering, spring force is widely used in various mechanical devices for controlling motion, storing energy, or providing support.

2.1 Different Types of Spring Force:

Different types include compression, tension, and torsion spring forces. These forces have multiple applications in pogo pins (Pogo Pins):

- Compression Spring Force: In pogo pins, compression spring force ensures a good contact between the pin head and the contact point. Pressing the pogo pin enables the pin head to effectively connect with the target point, transmitting signals or current.

- Tension Spring Force: Used in applications requiring stretch deformation, like stabilizing and ensuring durability of pogo pin heads. This force type prevents the spring pin from loosening or losing elasticity during use.

- Torsion Spring Force: Common in designs needing twist deformation, controlling rotation or angle adjustments in pogo pins. Precise control over spring twist characteristics ensures accurate operations and reliability in devices.

These spring force types are optimized in pogo pin designs based on specific operational requirements and environmental conditions, ensuring reliability and stability in functionality.

3. Basic Principles of Pogo Pins:

The key component affecting spring pin performance is the spring, which plays a crucial role in the entire needle structure. Its primary functions include providing pressure and resilience, impacting the effectiveness and durability of Pogo Pins.

3.1 Functions and Roles:

- Providing Pressure and Force: The spring in a spring pin delivers the required injection pressure, ensuring substances like medications or fillers are evenly and consistently injected into the skin or tissue. Its design and strength directly influence injection precision and effectiveness.

- Resilience and Stability: Well-designed springs offer excellent resilience, maintaining stable and precise injection actions, avoiding poor injection results due to spring failure or instability.

3.2 Benefits:

- Precision and Controllability: Quality springs ensure precise distribution of medications or fillers, enhancing predictability and consistency in treatment or cosmetic outcomes.

- Durability: Spring design affects the lifespan and performance stability of the needle, effectively extending the spring pin’s usage duration.

3.3 Effects:

- Enhancing User Experience: Well-designed springs minimize discomfort, such as pain or improper injection sensations, enhancing overall user experience.

- Safety: Spring design directly impacts injection safety, ensuring safe and effective delivery of substances, and mitigating safety risks due to spring-related issues.

Spring pin performance and effects heavily rely on spring design and material selection. Therefore, selecting and optimizing spring components is crucial for ensuring stability and performance in Pogo Pins.

4. Impact of Spring Force on Pogo Pin Performance

4.1 Role of Spring Force in Pogo Pins: Ensuring Stability and Reliability

4.1.1 Ensuring Stability:

- Maintaining Contact: Spring force ensures Pogo Pins maintain solid contact with contact points during insertion and removal, ensuring stable and continuous electrical signal or power connections.

- Adaptability: Spring force designs account for environmental changes like vibrations and temperature variations, ensuring stable connections unaffected by external disturbances.

4.1.2 Enhancing Reliability:

- Durability: Spring force selection affects Pogo Pin lifespan. Well-designed springs endure frequent insertions without failure, maintaining long-term stable electrical connectivity.

- Electrical Performance: Proper spring force guarantees sufficient contact pressure during connections, ensuring stable and efficient transmission of electrical signals or currents, preventing signal loss or increased resistance.

- Safety: Thoughtful spring force design minimizes risks of short circuits or other safety hazards during insertion, ensuring device and user safety.

By precisely designing and adjusting spring force, Pogo Pins maintain stable and reliable electrical connections across various usage environments and operational conditions, enhancing overall device performance and user experience.

4.2 Crucial Role of Spring Force in Pogo Pin Electrical Performance

- Contact Pressure and Stability: Spring force dictates contact pressure during Pogo Pin connections, directly impacting the quality of electrical signal transmission. Proper spring force maintains stable contact, preventing interruptions or interference.

- Reliability and Longevity: Spring force design considers long-term reliability, ensuring consistent performance even after multiple insertions. It avoids signal distortion or functional failures due to poor contact.

- Material and Manufacturing: Spring force selection correlates closely with Pogo Pin materials and manufacturing processes. Suitable materials and precise manufacturing ensure stable and consistent spring force, maintaining electrical characteristics within design requirements.

Spring force, a critical design parameter for Pogo Pins, guarantees excellent performance and long-term stability in electrical connections through precise control of contact pressure, stability, reliability, and manufacturing processes.

4.3 Significant Impact of Spring Force on Pogo Pin Lifespan and Long-Term Performance

- Insertion Count and Stability: Spring force directly influences contact stability during each insertion, ensuring reliable contact and minimizing impedance changes to extend Pogo Pin lifespan.

- Material and Stress Distribution: Spring force magnitude affects stress distribution within Pogo Pin springs. Improper force can concentrate stress, accelerating spring fatigue and risk of failure. Proper design ensures even stress distribution, prolonging spring lifespan.

- Environmental Adaptability: Spring force selection considers Pogo Pin usage environments, including temperature changes and humidity. Suitable force maintains stable electrical performance across varied conditions, enhancing long-term reliability.

- Design and Manufacturing Quality: Spring force design integrates specific Pogo Pin design requirements and manufacturing processes, ensuring stable and consistent force. High-quality design and manufacturing minimize lifespan reduction from force variations or instability.

Precise control of spring force size and quality effectively extends Pogo Pin lifespan and long-term performance, enhancing reliability and stability across diverse applications.

5. Optimization Strategies for Spring Force

5.1 Importance of Optimizing Spring Force in Pogo Pins

- Load Requirements: Initially, determine the maximum loads and pressures Pogo Pins will face in real-world applications. Spring force design should ensure stable connections and electrical contact under these conditions.

- Material Selection: Spring force is influenced by material stiffness and elasticity. Choose suitable spring materials (e.g., stainless steel) and determine appropriate hardness and modulus to prevent plastic deformation or failure during prolonged use.

- Geometric Design: The shape and structure of springs (e.g., coil count, diameter, length) directly impact spring force and stability. Precise calculations and simulations determine optimal geometric parameters to meet load and lifespan requirements.

- Preload and Resilience: Preload refers to initial spring force when Pogo Pins are not connected, affecting contact pressure and stability during connections. Resilience describes a spring’s ability to recover after force, impacting repeated connection performance.

- Environmental Factors: Consider usage environments like temperature changes, humidity, and vibrations, which affect spring material performance and lifespan. Thorough testing and consideration during design are essential.

- Manufacturing Precision: Design spring force with manufacturing process precision and tolerance in mind to ensure consistent and predictable force for each Pogo Pin.

Through precise engineering calculations and experimental validation, optimizing spring force design for Pogo Pins ensures overall performance, stability, and reliability meet product requirements and expected usage conditions.

5.2 Practical Application of Spring Force in Pogo Pins

5.2.1 Ensuring Stable Electrical Connections:

- The spring force in Pogo Pins dictates contact pressure during connections. Insufficient force may lead to poor contact or disconnection, while excessive force risks connector damage or difficulty in insertion and removal.

5.2.2 Enhancing Insertion Reliability:

- Appropriate spring force provides adequate resistance during insertion and removal, ensuring smooth operations without being too loose or tight.

5.2.3 Optimizing Product Lifespan:

- By adjusting spring force, you can reduce wear on connectors and extend product lifespan. For example, controlling preload to adjust force per Pogo Pin accommodates various insertion forces and environments.

By making these adjustments and optimizations, you improve product reliability and stability, ensuring excellent electrical connections across diverse applications.

Conclusion

We’ve covered the basic concepts and significance of spring force in Pogo Pins, discussing its impact on performance and stability. This includes:

- Electrical Connection Stability: How spring force maintains reliable electrical connections, preventing disconnection or increased resistance.

- Mechanical Durability: How spring force affects Pogo Pin lifespan and stability.

- Environmental Adaptability: How spring force performs under different temperature and humidity conditions.

Factors Influencing Spring Force:

- Exploring factors such as spring materials, design structure, and manufacturing processes that affect spring force size.

Future Trends in Spring Force Development:

- Discussing future applications and trends in spring force technology for Pogo Pins, including smart and adaptive technologies, new materials, and manufacturing techniques.

- Highlighting the importance of spring force in Pogo Pin performance underscores ongoing advancements driving broader applications across various fields. For high-quality spring force Pogo Pins, please contact us!