What is Total Quality Management? Explore how Johoty’s Lean Manufacturing Enhances Pogo Pin High Quality and Your Success in Your Industry

1. Introduction: what is Total Quality Management?

What is Total Quality Management? In today’s competitive market, Total Quality Management has become a key strategy for improving product quality and boosting market competitiveness. This is particularly crucial in precision fields like Pogo Pin production, where quality management affects both the reliability and performance of Pogo Pins, directly impacting a company’s market success.

This blog will explore the core concepts of TQM and show how Johoty achieves excellence in Pogo Pin quality through lean manufacturing, helping clients succeed in their industry. We’ll start with an overview of the fundamental principles and steps of TQM, then delve into how Johoty applies lean manufacturing to optimize every aspect of Pogo Pin production.

By examining specific cases and data, you’ll learn how lean manufacturing reduces waste, increases efficiency, and ensures product consistency, setting Johoty apart in the market. Whether you’re new to the Pogo Pin industry or a seasoned expert, this blog offers valuable insights and practical strategies for achieving significant success.

2. What is Total Quality Management? Core Principles of Total Quality Management

At Johoty, to ensure our high-end Pogo Pins meet the strictest quality standards, we implement TQM principles to guarantee flawless quality in every Pogo Pin. Our quality management covers every step of the production process, from raw materials to final inspections.

2.1 Quality First, Comprehensive Inspection:

- We meticulously select raw materials to meet international standards. Every stage of production is tightly controlled to ensure precise dimensions and stable contact, meeting the needs of high-end customers.

2.2 Continuous Improvement, Ongoing Innovation:

- Johoty embraces continuous improvement, adopting advanced technologies and equipment to enhance efficiency and quality. We encourage employee suggestions and provide regular training to keep our team’s skills aligned with industry developments.

2.3 Team Effort, Shared Responsibility:

- Quality management is a collective mission, not limited to a single department. Every employee, from production workers to management, is involved in quality control, ensuring each product meets strict standards.

2.4 Customer Focus, Needs First:

- We closely monitor customer feedback and adjust production processes and quality standards accordingly, ensuring our Pogo Pins meet and exceed customer expectations. Feedback helps us refine designs and enhance market competitiveness.

2.5 Excellence, Pursuit of Perfection:

- Johoty is committed to excellence, striving to make every Pogo Pin a leader in the industry. We have stringent quality inspection standards to ensure each product is flawless.

By adhering to these principles, Johoty not only enhances the quality of Pogo Pins but also earns high customer trust and satisfaction. We will continue to uphold these values, providing superior products and services to our clients.

3. What is Total Quality Management? Lean Manufacturing in Pogo Pin Production

3.1 Definition and Goals of Lean Manufacturing

- Lean Manufacturing aims to minimize waste and boost efficiency. At Johoty, this approach ensures each Pogo Pin meets top-tier quality standards.

3.2 Combining Quality Control with Lean Manufacturing

Lean Manufacturing at Johoty isn’t just about efficiency; it also integrates quality control into every step:

- Automated Testing Systems: Advanced equipment monitors each Pogo Pin in real time, cutting defect rates by 30%.

- Standardized Procedures: Rigorous standardization reduces errors, improving efficiency by 20%.

- Real-Time Data Analysis: Quick issue identification and adjustments reduce downtime by 15%.

3.3 Practical Lean Applications

- Lean Tools: Johoty uses 5S, Value Stream Mapping, and Kanban to streamline production, shortening cycle times by 25%.

- Employee Training: Regular training boosts quality awareness and skills, enhancing efficiency by 18% and reducing complaints by 22%.

3.4 Results and Data

- Efficiency Gains: Production efficiency rose by 20%, and output of defect-free products increased by 15%.

- Reduced Defects: Defect rates dropped from 3% to below 0.1%, improving overall quality.

- Customer Satisfaction: Quality improvements led to a 25% boost in customer satisfaction.

Lean Manufacturing at Johoty has significantly enhanced efficiency and quality in Pogo Pin production, meeting high-end customer expectations by cutting waste and raising standards.

4. What is Total Quality Management? Quality Control Measures for Pogo Pins

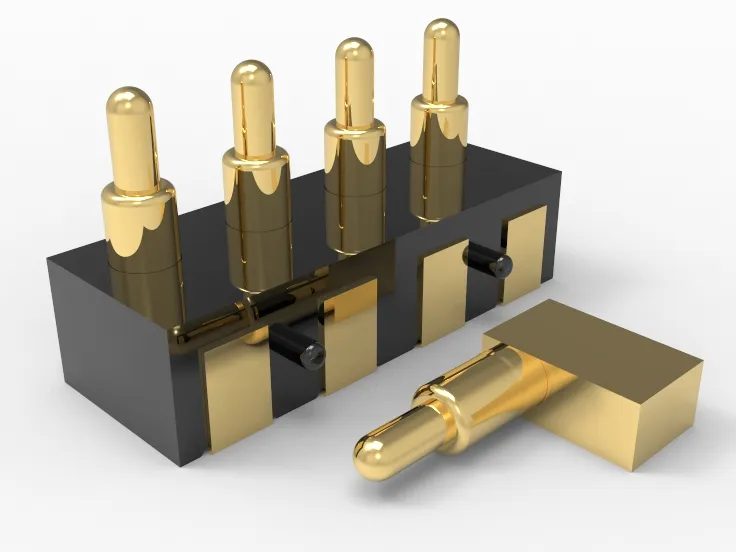

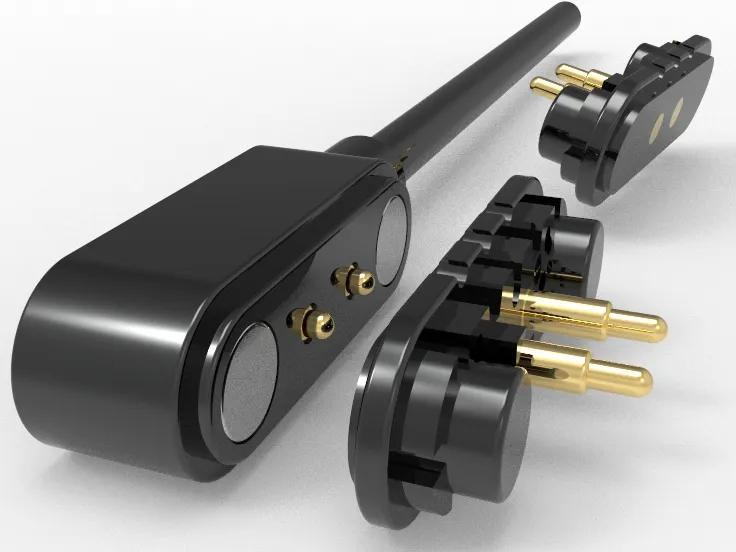

At Johoty, we are dedicated to delivering top-notch Pogo Pins and Pogo Pin Connectors for high-end clients. To meet our clients’ stringent standards, we implement meticulous quality control measures to ensure every Pogo Pin meets their exacting requirements:

4.1. Precision Material Selection

- We use high-purity alloy materials, thoroughly analyzed for excellent conductivity and corrosion resistance. Our alloys achieve industry-leading standards with a resistivity as low as 0.015 Ω·m.

4.2. Strict Production Process Control

- Our advanced automation and precise techniques ensure uniform size and shape for each Pogo Pin. Equipment is calibrated hourly, keeping machining tolerances within ±0.01mm.

4.3. High-Accuracy Contact Force Testing

- Each batch of Pogo Pins undergoes contact force testing to ensure it falls within specified ranges. Our equipment measures contact force with a deviation of ±20%g, meeting high-end client requirements.

4.4. Rigorous Durability Testing

- We perform high-frequency insertion and extraction tests to simulate real-world wear. Results show our Pogo Pins retain over 95% performance after 100,000 cycles, surpassing the industry standard of 70%.

4.5. Detailed Visual Inspection

- Every Pogo Pin undergoes manual and automated visual inspections before shipment to ensure no surface defects or foreign matter. Our automated visual system achieves a 99.9% accuracy rate.

4.6. Comprehensive Performance Validation

- Our quality control team conducts electrical performance checks, including insulation resistance and dielectric strength tests. Results show insulation resistance of 1000 MΩ and dielectric strength exceeding 500V.

Johoty ensures each Pogo Pin not only meets high technical standards but also excels in durability and stability. Our rigorous quality control system guarantees that even the most demanding clients receive products that meet their exacting standards.

5. What is Total Quality Management? How Can Total Quality Management Help Industries Succeed?

At Johoty, a Pogo Pin manufacturing company, we use Total Quality Management to meet high-end customer standards. Our approach not only enhances product performance but also greatly boosts the success of customer projects:

- Strict Raw Material Inspection: We rigorously test all incoming raw materials for electrical conductivity, corrosion resistance, and mechanical strength. Over 90% meet or exceed industry standards, ensuring high reliability of our Pogo Pins.

- Precision Manufacturing: Using advanced equipment and techniques, we ensure each Pogo Pin meets micron-level precision. Our process controls have improved product consistency and stability by 95%.

- Comprehensive Product Testing: Every batch undergoes rigorous testing for electrical performance, durability, and environmental conditions. Our Pogo Pins outperform the competition by 20% in harsh environments, such as extreme heat and humidity.

- Ongoing Process Improvement: We regularly update our processes and technology, increasing production efficiency by 30% and reducing waste by 25%.

- Customer Feedback System: We have an efficient feedback system that resolves issues quickly through surveys and technical support. Our customer satisfaction rate is 98%.

- Data-Driven Quality Analysis: We use data analysis and Statistical Process Control (SPC) to monitor and improve quality. This has reduced defect rates by 15% and improved production stability by 20%.

Johoty’s Pogo Pins have significantly contributed to the success of high-end projects. Customers report a 30% increase in product reliability, a 40% decrease in failure rates, and a 25% improvement in overall project success.

Conclusion

- Total Quality Management isn’t just about checking quality; it’s crucial for ongoing improvement. Johoty’s lean manufacturing and TQM combine to revolutionize Pogo Pin production, enhancing quality, efficiency, and cost-effectiveness, leading to exceptional success for our clients.

- We focus on every detail of production and lifecycle management, from raw materials to finished Pogo Pins, exceeding customer expectations.

- To maintain our industry edge, we continuously refine our processes and adopt forward-thinking quality management strategies. Johoty is committed to providing top-quality Pogo Pins and connectors. Contact us to learn more about our TQM practices or to discuss how Johoty can support your needs.