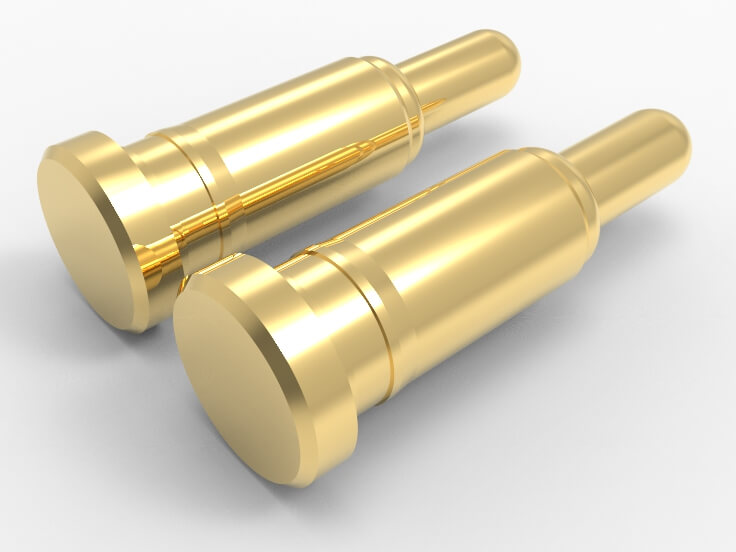

Best SMT Pogo Pins China Manufacturer Automatic Installation

SMT pogo pins are precision connectors for surface mount, spring-pressed and electrical connections. Brass plunger and barrel, built-in spring, transmit high-frequency signals, connect test interfaces and modules. High compression force, automated assembly, strong durability for small, high-density consumer electronics, medical equipment, etc. Johoty offers perfect customization.

Features:

- Surface mount, used for SMT assembly.

- Resistant to use, high durability, long lifespan.

- Diversified sizes, customized specifications.

- Good electrical feature, stable signal transfer.

- Compact structure, saving circuit board space.

Antioxidant, corrosion resistance, reliability.

SMT Pogo Pins Series

SMT pogo pins, Plunger shapes: round or dome tip for flexible contacts and smaller contact areas. Flat tip for low voltage, high current, and high power. Pointed tip for high-density circuit boards, small solder pads, or small connections. Pyramid tip for multi-point contact, increasing contact area and evenly distributing pressure. Chamfered tip is used for smooth contact and to avoid sharp contact. Ball tip for high current and high power. Elliptical tip is used to increase contact area without increasing excessive contact pressure. Multiple star tips are used for high-density contact. Materials: Brass, stainless steel 304, 316, tellurium copper, beryllium copper. Plating: gold, silver, nickel, palladium, platinum, rhodium, ruthenium, composite electroplating.

Category | Detailed Description |

|---|---|

| Product Category | SMT Pogo Pins with variations in pin diameter, stroke length, and mounting options, tailored for surface mount technology (SMT) applications. Including diameter from 0.3mm to 5mm, stroke from 0.3mm to 3mm, length from 1.6mm to 100mm, spring force >15gf, rating current >0.1A. Types: Micro, Short, Extended, Waterproof, Protected Cap, High Current, Customizable, etc. |

| Target Customers | Prototype production, wireless charging, research and development testing. Electric vehicles, fast charging equipment, auto drive system. Portable diagnostic equipment, wireless communication, convenient monitoring equipment, network equipment. Testing equipment, mobile phones, robots. Laptops, control systems, smart wearable devices. |

| Applications | Ideal for circuit board connectivity, IoT devices, medical equipment, battery test, industrial control, intelligent wearable devices, robotics technology, and automotive electronics, where space efficiency and high durability are key. |

| Function Specs | High reliability, excellent current-carrying capacity, resistance to wear, SMT automatic mounting, stable electrical contact, withstand multiple insertions and removals, spring force 15gf~800gf, contact resistance ≥ 15mΩ, stainless steel, brass, Voltage <500V, Current <50A, life cycles <400,000 times, Gold plating, silver, palladium, platinum, nickel, etc. |

| Brand Info | Johoty brand, emphasizes high quality, precision engineering, and dedication to supporting sustainable technology. Known for its commitment to client-specific customizations and rigorous quality standards. |

| Price | $0.10 – $10.00 per unit based on order volume and customization level. |

| Quality Standards | Materials: ISO9001, RoHS, ASTM B578, ASTM B488. Electrical: IEC, UL, ISO 8501-3. Mechanical: IEC, MIL-STD-202, JIS C 8715. Thermal: IEC, IPC, UL 94. Reliability: IEC, MIL, ISO. Certification and Safety: ISO, RoHS, REACH, UL. Appearance: IPC, ICE. Insertion and Functional Testing: IEC, IPC, MIL. Packaging and Shipping: IEC, IPC, ASTM. Corrosion Resistance: ASTM, IEC.. |

| Where to go | Johoty’s website (https://johotypro.com), Johoty CFT team (cft@johoty.com) for proposals, solutions, samples, small production, and mass production. |

| Customer Service | 24/7 customer support, consultation on product specifications, customization assistance, and ASS, Dedicated support teams for major markets. |

| User Feedback | Very reliable long-term performance, meet high-precision requirements, high durability & long lifespan. Satisfied with diverse applications, meet design needs of different products, convenient for production lines. Fast delivery, quick feedback, high efficiency. Ensure high quality at competitive prices, offer long-term cooperation discounts, help customers reduce production costs. Continuous innovation and R&D support. |

| Market Edge | High-density connection, reliable and durable, reducing costs. High precision and stability, suitable for various applications, improving product quality. Convenient assembly and maintenance, excellent high-frequency performance. Customized design, anti-interference, capable of handling various complex work environments. |

Johoty offers highly competitive prices while holding excellent quality. By optimizing production processes, large-scale procurement, and strict cost control, we can provide clients with cost-effective SMT pogo pins solutions. This cost advantage helps clients obtain high-quality SMT pogo pins within budget, effectively reduces production costs, enhances product market competitiveness, and helps clients gain an advantage in price.

We adopt advanced CNC, assembly and inspection equipment and strict quality control to ensure SMT pogo pins meets international quality standards, providing reliable performance and durability. Through multiple globally recognized quality guarantees, such as ISO certification, RoHS compliance, ASTM, UL certification, etc., we promise to provide customers with stable and durable high-quality pogo pins, thereby adding value to clients’ products and enhancing market competitiveness.

We provide flexible customization and can customize SMT pogo pins with different specs and functions according to specific client needs. Whether in terms of size, shape, contact force, high current, or special materials, high temperature resistance, etc., Johoty can provide precise solutions based on customers’ requirements. Through personalized customization, customers can obtain solutions that better meet their product needs, enhancing product uniqueness and market competitiveness.

With efficient production processes and strong production capabilities, Johoty can ensure fast delivery and meet customers’ urgent needs. We can provide flexible delivery times and reliable logistics services for both large quantities of SMT pogo pins and small batches of prototypes. This can ensure clients receive pogo pins on time and avoiding project delays caused by long production cycles. This efficient and on-time delivery is an important advantage for Johoty to firmly establish a foothold in the market.

Why Choose Johoty's SMT Pogo Pins?

Johoty’s SMT pogo pins give you high quality, customization, fast delivery, and cost advantages. Help you reduce production costs and accelerate market launch. Johoty is your reliable partner.

SMT Pogo Pins Applications

Smart Wearable Devices

SMT pogo pins provide stable electrical connections for smartwatches, fitness trackers, and more. Compact design, supports high-frequency charging, ensuring long-term efficient operation of the equipment. High durability, suitable for daily use and frequent charging. Through surface mounting technology, space utilization has been optimized, and the reliability and lifespan of equipment have been enhanced.

Wireless Earphones and Earplugs

Accurate SMT pogo pins provide efficient charging solutions for wireless earphones. Lightweight design, adaptable to various headphone shapes, ensuring good charging contact. No additional plug is required, simplifying designd and improving overall waterproof and dustproof of clients’ product. Enhance user experience and extend the battery life of headphones.

Medical Equipment and Sensors

In portable medical devices, SMT pogo pins provide reliable power transfer and data connections. Durable material, strong corrosion resistance, suitable for various environments. Its precise surface mounting enhances equipment compactness and precision. Ensure efficient and safe operation of medical equipment, and improve patient care quality.

Consumer Electronics Products

SMT pogo pins are widely used for convenient charging and data transfer interfaces. Minimalist contact design improves current transfer efficiency and shortens charging time. Surface mounting solutions help optimize equipment thickness and meet the market’s demand for lightweight electronic products. Ensuring long-term stable use is a core component of modern consumer electronics.

FAQ

Can SMT pogo pins withstand extreme temperatures?

Johoty considers temperature range when designing SMT pogo pins, which can work stably at high temperatures of 150°C or low temperatures of -55°C. Their contact points are plated-gold beryllium copper and different special materials. This can minimize the affection from temperature differences. It can usually work normally in -40°C to +125°C. The electronic device reliability is very important. It is suitable for harsh environments.

Can SMT pogo pins adapt to circuit boards of different thicknesses?

The contact pin length and elasticity of SMT pogo pins can adapt to circuit boards of different thicknesses. They will automatically adjust the pressure according to circuit board thickness during contact process. Even if changing circuit board thickness, the contact points can always remain stable. Adapting to multiple specifications enhances design flexibility. Reserve suitable installation space during design.

Why do SMT pogo pins have different plunger shapes?

SMT pogo pins have various plunger tip shapes, star, spherical, cup, cylindrical, and conical. Different contact methods can optimize contact quality according to actual usages. The spherical design is suitable for frequent connection, and has good durability. Cylindrical shape is suitable for stable connection and reduces contact impedance. Cone contact can increase pressure and adapt to more equipment.

Will SMT pogo pins be affected by vibration?

SMT pogo pins have strong anti vibration. Due to spring design and contact points, the vibration impact can be effectively reduced. Even if strong vibrations are generated during device operation, they can still maintain a stable connection. Spring to compress or stretch helps absorb vibrations. Suitable for high vibrative automobiles and aviation.

How to avoid contact point wear of SMT pogo pins?

The key to avoiding contact point wear is to use right designs and appropriate materials. Contact points are usually made of high wear-resistant gold-plated copper beryllium copper. Reducing frequent excessive contact can extend its lifespan. By precisely controlling the contact pressure, unnecessary friction can be reduced. It can effectively extend lifespan by regular inspection and routine preventive maintenance.

How can SMT pogo pins improve connection stability?

SMT pogo pins ensure stable electrical contact with each connection by designing pressure and spring contact method. The spring force can be adjusted according to usage needs to ensure that it doeen’t loosen for long time. Fully consider contact resistance during design to reduce poor contact risks. Good contact stability helps improve equipment operation efficiency. Suitable for high stability.

Can SMT pogo pins work in humid environments?

Johoty’s SMT pogo pins are specially designed to maintain good performance effectively in humid environments. The contact points are usually coated with anti-corrosion layer to prevent erosion by water vapor and oxides. The spring and conductive parts aren’t easily damaged by moisture. Johoty once designed waterproof magnetic connectors for EMS systems, with a female end that reaches IP67 and 6-layer composite electroplating, which can resist solvent corrosion and can be cleaned in washing machines. For some devices that require waterproof, special protective measures will be taken during design. Ensure long-term stable work.

Can SMT pogo pins be used in high-frequency applications?

SMT pogo pins perform excellently in high-frequency. Its contact design effectively reduces signal loss and ensures stable transfer of current and signals. By optimizing the shape and material of the contact points, high-frequency interference can be reduced. Its structure can withstand high-frequency currents and signals. Suitable for high-frequency communication and wireless devices.

Benefits to Clients:

High precision and reliability ensure stable connection

Johoty’s SMT pogo pins use advanced 5-axis CNC to ensure accuracy and consistency at each contact point. No matter how the customer’s equipment works, it can maintain stable electrical connections. Each pogo pin undergoes strict quality control and can withstand up to 200,000 cycles of connections without experiencing poor contact or disconnection issues. We are committed to providing durable and reliable connectivity solutions to keep our customers’ devices running efficiently over long use.

Optimize cost-effectiveness and reduce overall costs

We help customers reduce overall costs through precise design and efficient production. Compared with traditional connection methods, SMT pogo pins can reduce manual soldering time, lower complex component demands. We also offer mass production discounts to reduce the cost of individual pogo pins. These saved funds can further optimize pogo pins design or invest in other projects, allowing customers to enjoy more competitive prices while maintaining high quality.

Flexible customization for diverse needs

Johoty’s SMT pogo pins offer a variety of customization, allowing for the adjustment of size, shape, stroke, elasticity, and contact method according to clients’ needs. We can provide customized solutions for both compact designs and special current transfer. Customers can choose the most suitable specifications based on product needs, avoiding unsuitable generic products. Our flexible customization enable customers to optimize product and design to the fullest extent possible.

Fast delivery and shortened time to market

We carefully optimize our production processes for fast delivery and highest quality. Through sound supply chain management and inventory reserves, we can complete mass production in a short time. This is crucial for Johoty’s client who want public quickly. Customers don’t need to wait for delivery for a long time and can complete product development and market release ahead of schedule. Johoty can deliver on time or even ahead of schedule, helping customers seize market opportunities and enhance competitive advantage.

High durability and long-term stability, reducing maintenance costs

SMT pogo pins are made of gold-plated brass or stainless steel with highly wear-resistant and corrosion-resistant. This can ensure high performance and stability during long-term use. They are designed to withstand extreme temperature changes, vibrations, and friction, reducing preventive maintenance and repair costs caused by poor contact or damage. We guarantee that each pogo pin has excellent durability, and customers don’t need to replace it frequently during long-term use, greatly reducing operational and maintenance costs. Our SMT pogo pins can work reliably in harsh, ensuring long-term stable equipment.

Professional technical support to ensure customers have no worries

We provide our customers with professional and precise technical support to ensure the best experience when using Johoty’s SMT pogo pins. Our CFT team provides detailed technical consultation and assistance from SMT pogo pins selection to installation guidance. When customers encounter various problems during use, CFT team can quickly respond and always provide effective solutions. Customers can confidently entrust technical issues to Johoty, allowing Johoty’s clients to contribute to core business. Our SMT pogo pins and professional services provide customers and end-users with happiness every day.