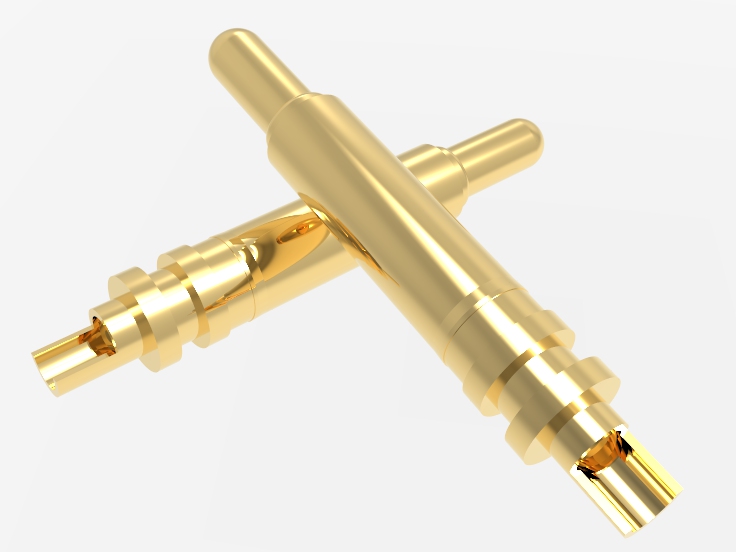

Best Solder Cup Pogo Pin China Manufacturer Unique cup shape

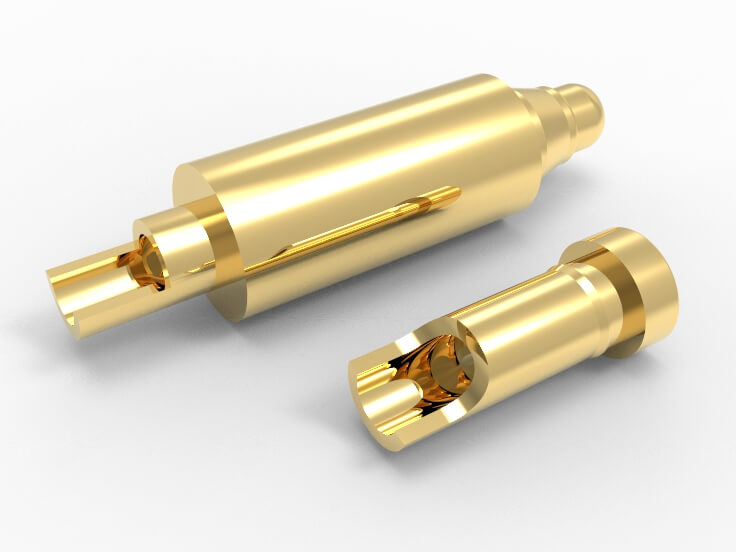

Solder cup pogo pin has a tail pin of cup-shape for soldering or connecting cable. Undertaking high voltage and high current, with excellent conductivity, high-speed signal transfer, and stability. Gold-plated tellurium, beryllium copper, brass. Johoty provides customization to fully meet clients’ requirements.

Features:

- Solder cups are easy to install quickly.

- Gold-plating ensures smooth signal flow.

- Special design for up to 300,000 cycles.

- Precision machining of brass or stainless steel.

- Quality spring ensures stable pressure.

- Customized size, current, and performance.

Solder Cup Pogo Pin Series

Solder cup pogo pin has thin wire soldering, normal wire soldering, high current soldering. The current ranges: <1A, 1A to 5A, and 5A to 5A. Plunger tips have flat heads, round, ball, pointed, cups, stars, crowns, etc. Customizable plunger stroke: 0.20mm ~ 10.00mm. Lifespan ranges from 10,000 to 300,000 cycles. Raw materials: brass, beryllium copper, SUS303/304/316/316L, Copper telluride, etc. Plating: Gold, silver, rhodium, ruthenium, nickel, palladium, platinum, composite electroplating. Johoty can provide customization.

Category | Description |

|---|---|

| Product Range | Solder cup pogo pin include standard, high-temperature, high-current, waterproof, low resistance, self-locking, spring-loaded, micro-sized, customizable, high-frequency, and insulation. It can handle various current loads from 0.01A to 50A. Perfect for both low-profile and high-precision applications, serves multiple efficient electrical connections. |

| Target Clients | Designed for founders, CTOs, managers, electronics engineers, procurement managers, and manufacturers in innovative R&D, automotive, wireless devices, medical devices, telecoms, etc. |

| Applications | Ideal for circuit boards, charging/signal/data interfaces, and portable electronics. These pogo pins also serve in highly reliable aerospace and defense, medical, automotive, and robots for frequent use and movement. |

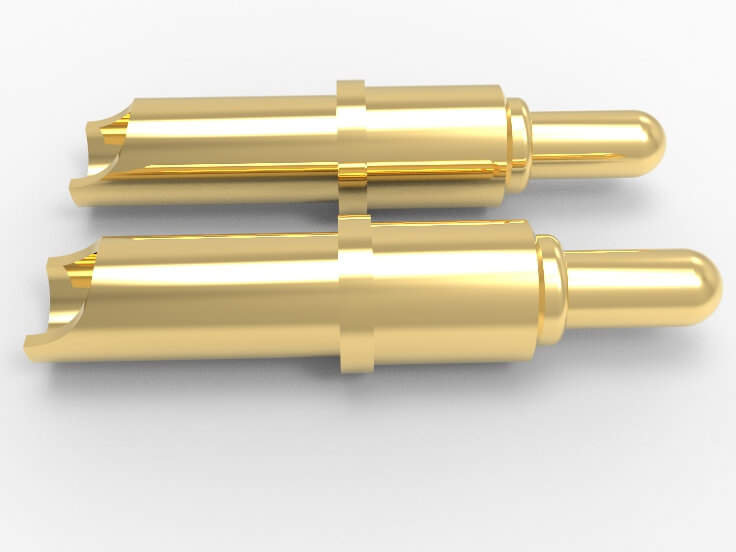

| Solder Cup Sizes/Shapes | Diameter: 0.50mm, 0.80, 1.00, 1.50, 2.00, 2.50, 3.00, custom. Shapes: Standard/deep, round/square, standard/widened oval, sealed. Corrosion-resistant, custom shaped, semi-round, extended round/square. |

| Function | Solder cup pogo pins feature high spring force, high current, low resistance, and excellent wear resistance. They accommodate axial and radial movement, ensure stable contact under mechanical stress, ideal for dynamic, high-frequency connections. |

| Technical Specs | Precision machined, gold-plated for corrosion resistance, with length 4.60~50,00mm, spring forces 15 ~ 3,000gf. Temperatures -40°C to +85°C, stroke 0.20~10.00mm. Cater to industry-specific durability and stability. |

| Brand Info | Commitment to innovation, Johoty has over a decade of experience in connector technology, focusing on high quality to meet clients’ complete customization with the best costs and effective solutions. |

| Pricing | $0.50 to $5.00 per unit based on specifications, order volume, complexity, and customization needs. Ensure competitive pricing. |

| Quality Standards | Adheres to ISO 9001, RoHS, REACH, MIL-PRF, ASTM, IEC, etc. Life cycles of 10,000-300,000 insertions. |

| Where to buy | Johoty website (https://johotypro.com), and Johoty CFT team (cft@johoty.com) for streamlined, efficient ordering and delivery. |

| Customer Support | 24/7 technical support, customization services, and responsive post-sale assistance to address each client’s issues clients’ high satisfaction with every order. |

| User Feedback | High service life and electrical performance, meet high quality requirements. Quick response and quick resolution of technical issues. Customized services, on-time delivery, rapid completion of large-scale production with high quality. It has leading advantages in spring pressure and contact resistance. Excellent cost-effectiveness for long-term cooperation. |

| Advantage & Ediges | Feature high precision and consistency, provide various sizes, strokes, materials, contact forces, shapes, and electrical specifications. Reduce production costs while ensuring quality. Effectively breaking through high-frequency, high current, and resistance control for customers. Provide customers with fast delivery to ensure projects are on track. Quickly respond to bulk orders and urgent order requirements, provide professional technical consultation and product selection suggestions. Timely resolution of customer issues, in compliance with international certification. |

Johoty’s solder cup pogo pin adopts advanced production and precision equipment. Each pogo pin passes 23 strict quality tests for high performance. Compared with other competitors, Johoty’s pogo pins have excellent spring life and contact resistance, and can withstand higher frequency connections. Ensure efficient and stable electrical connections. Our spring loaded pins have passed ISO 9001, REACH, RoHS, ASTM, etc. are widely used in electronics, automotive, medical, and others, and have been recognized by customers.

Johoty effectively reduces production costs through precision CNC manufacturing and automated production, provides customers with competitive prices. Compared with similar suppliers, our solder cup pogo pin has uncompromising quality, but its price is more advantageous, which can help customers reduce procurement costs. We also offer significant discounts for clients’ long-term business and flexibly customize quotes based on order volume. To ensure clients receive maximum cost-effectiveness while ensuring quality, thereby improving overall procurement efficiency.

It is urgent for our customers in supply chain, so Johoty is committed to providing efficient and safe delivery. We can deliver both large and urgent orders quickly within a short time. With global logistics, Johoty can ensure timely delivery to various warehouses or offices and provide tracking to ensure clients are informed of items status in time. We also have sufficient inventory of raw materials, which enables Johoty to quickly answer clients and minimize inventory pressure and production stagnation.

Johoty provides comprehensive professional support to help clients solve selection, technical requirements, and product installation. Our CFT team can provide customized solder cup pogo pin solutions based on customer needs, ensure accurately match project requirements. For size, material requirements, and unique electrical performance, Johoty can provide personalized solutions in short time, ensure smooth progress of customer projects.

Why Johoty's Solder Cup Pogo Pin?

Johoty’s’ solder cup pogo pin, you will receive excellent quality, stable electrical performance, long lifespan, competitive prices. Fast delivery and customization, high cost-effectiveness, professional services help clients reduce procurement costs and improve overall supply chain KPIs.

Solder Cup Pogo Pin Applications

Medical equipment connection solution

Precise design ensures efficient connection with complex medical equipment. Provide stable low resistance to meet strict requirements of surgical and diagnostic devices. Corrosion resistant material, suitable for high disinfection frequency. Meet high precision and long lifespan.

Consumer electronics charging and data transfer

Adapt to multiple interfaces to simplify wearable device connection. Supports fast charging, high-speed data and signals. Reliable contact ensures low resistance and sustained performance. Compact design, suitable for lightweight devices.

Connection of automotive electronic modules

Resistant to high temperature as well as high humidity, meet automotive’s stringent requirements. High elasticity structure ensures stable contact during vibration. Suitable for efficient connection of ADAS, car charging and other modules. Extend lifespan, reduce costs.

Intelligent connection of industrial equipment

Withstand high-intensity workloads and ensure industrial stability. High conductivity for high-speed data exchange and power transfer. Adapt to customized design to meet industrial automation. Strong durability, reducing equipment downtime and replacement frequency.

FAQ

How can solder cup pogo pin improve connection stability?

Solder cup pogo pin provides stronger elastic contact force, ensures long-term stable connection. It helps minimize poor contact risks. High quality materials make contact points more durable. Stable electrical contact prevents signal loss. Precise structure makes contact more firm and reliable.

Is solder cup pogo pin suitable for high-speed data or signals?

Solder cup pogo pin is suitable for high-speed data or signals. It can reduce contact resistance and improve signal transfer efficiency. Precise contact surface ensures signal stability. Adapt to high-frequency applications, reduce interference and latency. Excellent performance meets high demand requirements.

How does solder cup pogo pin perform in high temperatures?

Johoty’s solder cup pogo pin performs well at high temperatures. The material has high heat resistance and isn’t easily deformed. It can maintain stable electrical contact to ensure equipment operation. Suitable for high-temperatures of electronic devices. Under high temperature, connection remains high reliable.

Is solder cup pogo pin suitable for different sizes?

Solder cup pogo pin offers multiple size options to meet different devices. Adjustments can be made according to circuit board space. Adapt to multiple designs to meet different requirements. Accurate dimensions and specifications ensure accurate connections. Suitable for customized projects and small-scale production.

Can solder cup pogo pin withstand frequent operations?

The pogo pins can withstand a large number of contact without damage. High elasticity materials provide stable contact force. Its design ensures consistency every time it is plugged in or unplugged. After prolonged use, contact points remain reliable. Suitable for applications require frequent disconnection.

Is it difficult to install solder cup pogo pin?

Solder cup pogo pin is easy to install for automated production. It can be installed quickly and save labor time. The design is simple for our clients, it is easy to locate. Even complex circuit boards can be quickly adapted. Reduced complexity of traditional connections.

Can solder cup pogo pin effectively reduce electrical noise?

Johoty’s pogo pins can effectively reduce electrical noise. Its low contact resistance can effectively reduce signal interference. Compact structure prevents external noise from entering the circuit. Optimized electrical contacts enhance signal quality. Suitable for high-end devices that require high signal integrity.

How does solder cup pogo pin perform in high vibration?

The solder cup pogo pin can maintain stability in high vibrations. Its structural design provides sufficient contact force. High elasticity ensures contact continuity. Can effectively prevent disconnection caused by vibration. Suitable for industrial and automotive electronic devices that require vibration resistance.

Benefits to Clients

High-reliability connection

Solder cup pogo pin provides long-term stable electrical connection, suitable for harsh industries. With high-quality materials and Johoty’s precise designs, we can ensure efficient signals, reduce poor contact. High reliability enables stable operation of electronic devices for frequent plugging and high vibration. Customers can trust our pogo pins, which can help clients ensure long-term stability and overall system efficiency. It can avoid equipment failures and performance degradation caused by poor contact.

Improve work efficiency

Solder cup pogo pin installation is fast and simple, greatly reducing production cycle. Johoty’s designs optimize connection process, simplify assembly steps, and reduce manual operation time. On complex circuit boards, precise installation can be easily completed, avoiding manual soldering. Efficient installation directly reduces production and maintenance time, allows customers to complete product delivery faster. Solder cup pogo pin improves the efficiency of the entire production line and reduces downtime during production.

Long service life

Johoty’s solder cup pogo pin focuses on extending its lifespan, ensuring stable performance after frequent operation. High elasticity contact points can resist repeated friction without losing elasticity, maintaining long-lasting electrical contact. Customers don’t need to worry about maintenance costs and downtime, thereby improve equipment overall service life. Durability makes our pogo pins an ideal choice for high-frequency usage, reduces replacement frequency, and lowers operating costs.

Adapt to various application requirements

Our solder cup pogo pin offers multiple specifications and size to meet different application. For complex PCB designs and specific industrial equipment, we can find suitable solutions. Our pogo pins perform well in medical, automotive, and communication industries, meet special requirements of various customers. Flexible customization and precise design enable customers to efficiently apply in multiple projects. It can meet both large-scale production and small batch customization.

Optimize cost control

Solder cup pogo pin offers competitive prices and high quality, helps customers achieve cost optimization. Due to our well-designed and efficient production, we can reduce production costs and provide feedback to our customers. Customers can enjoy performance improvement from high-quality solder cup pogo pin and reasonable cost control. This can achieve lower procurement and long-term costs. Compared to other connectors, Johoty’s solder cup pogo pin offers higher cost-effectiveness. It is an ideal choice for effectively controlling overall project budgets.

Excellent anti-interference performance

Johoty’s solder cup pogo pin has excellent EMI and vibration resistance, ensuring stable signal transfer. Its design effectively reduces the impact of external noise and vibration for industrial automation, communication equipment, high interference, etc. Customers can confidently apply our solder cup pogo pin to highly sensitive systems, improve system reliability and avoid equipment failures and performance degradation. Solder cup pogo pin can provide customers with continuous and stable support in high temperature, high frequency, and complex environments.