Best Threaded Pogo Pins China Manufacturer Stable Locking

Threaded pogo pins have sturdy threads that are stable and reliable for electrical connections under vibration or movement. High durability, excellent conductivity in harsh and high-end connection based on brass or beryllium copper gold plating. Johoty offers perfect customization.

Features:

- Stable thread, long-lasting, reliable connection.

- Anti-seismic & loosening for dynamic uses.

- Material options, durable, corrosion-resistant.

- High precision, excellent contact performance.

- Fit high frequency and low impedance conduction.

- High-temp resistance for extreme environments.

Threaded Pogo Pins Series

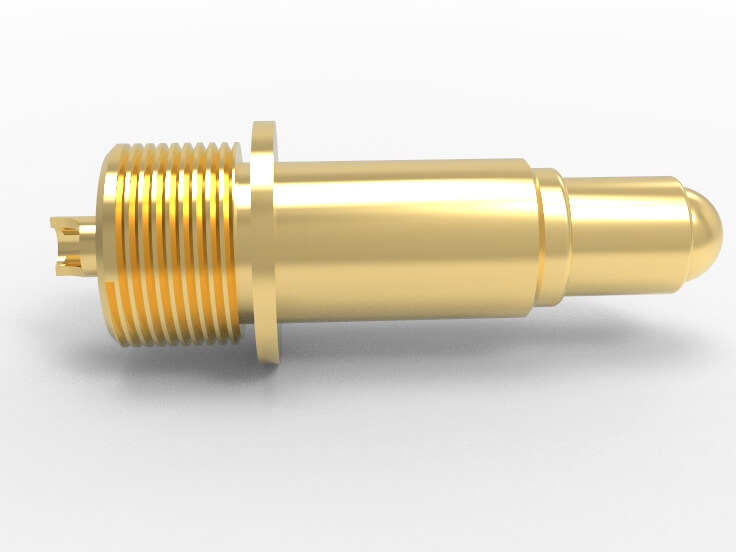

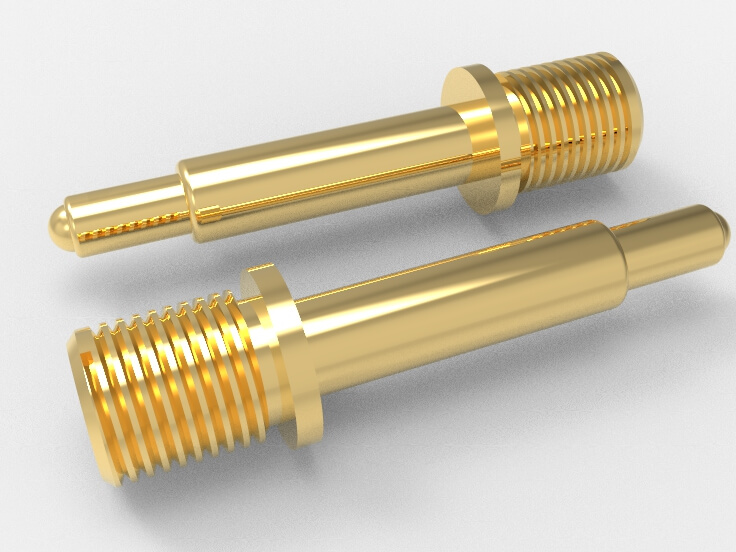

Threaded pogo pins.

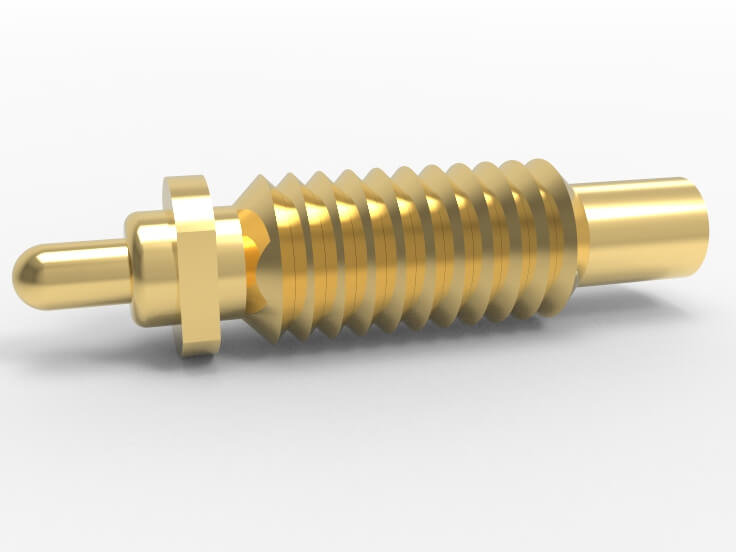

- Design and Construction: fix the device slot with threads, avoid poor contact caused by vibration or insertion and extraction operations, suitable for high-frequency connection or unstable environments. The threaded part adopts precision cutting to ensure stability and durability, ensuring firm contact and insertion stability.

- High-precision Spring: Made of high-quality piano steel, it effectively resists contact changes caused by vibration or mechanical loads.

- Electrical Contact: low impedance, high conductivity. High Wear, Corrosion Resistant Materials: stainless steel or gold-plated copper, resistant to moisture, chemicals, and oxidation.

- Adapt to Harsh Environments: -40°C~+125°C, vibration, high humidity, explosion-proof, waterproof, dustproof customized.

- Specifications: Length 6.00~70.00mm, outer diameter M1.0~M12.0, voltage <500V, current <200A, flexible customization.

| Category | Detailed Description |

|---|---|

| Product Category | Threaded inserts, top thread, middle thread, bottom thread, dual thread, bottom threaded hole, threaded guide, adjustment thread, and custom thread. Robust stability under vibrations or movement. |

| Target Customers | Electronic and equipment manufacturers, automation and industrial, automotive electronic, communication, medical, testing equipment and instruments, customized product enterprises, and R&D institutions. |

| Applications | PCB connection & tests, connection modules, industrial automation & control, automotive electronics, communication & data transmission, medical instrument connection, medical test & debug, electrical test & signal test, simulation & automation test, wearable devices, smart home devices. |

| Function & Specs | Low contact resistance, high conductivity, >10,000 cycles, effective response to vibration and impact, length 6.00-70.00mm, diameter M1.0~10.0, voltage <230V, current <120A, – 40°C~+125°C, threaded fixing design, customizable installation & shapes, gold/silver/nickel plating. |

| Screw Thread Types | M1.0x0.25, M1.2×0.25, M1.5×0.35, M2.0x0.4, M2.5×0.45, M3.0x0.5, M4.0x 0.7, M5.0x0.8, etc. |

| Brand Info | Johoty, combines engineering excellence with precision and durability in connectivity solutions. We’ve earned a reputation for customized designs and superior customer support, aiming to exceed expectations. |

| Price Range | >$0.10 per unit for basic models, higher due to material and precision specs. Varies based on size, customization level, and volume. Discounts for bulk orders. |

| Quality Standards | Manufactured to meet ISO, IEC, RoHS, REACH with a focus on longevity. Each pogo pin passes 10,000+ connection cycles. |

| Where to buy | Johoty website (https://johotypro.com), and Johoty CFT team (cft@johoty.com). WhatsApp/Tel./WeChat (+86 18007608187), Skype (alfredyou2013). |

| Customer Support | 24×7 technical support, easy warranty services, and personalized consulting for custom requests, technical documents, user manuals, instructional videos, etc. |

| User Feedback | High satisfaction with connection reliability, durability, and custom designs. |

| Market Edge | High durability, precision, and reliability in various industries. The price can be higher than basic pins due to specialized materials and designs. Competitive edge lies in superior longevity and customized options. |

Johoty’s threaded pogo pins are processed using precision 5-axis CNCs, ensuring accurate threads for each pogo pin and improving contact stability and long-term reliability. Compared to competitors, Johoty’s thread accuracy is high, which can effectively avoid errors during assembly, ensure perfect coordination with different devices, meet customers’ needs for high-precision connections. And, with highly competitive prices that fit customers’ budgets.

Johoty uses gold plating, palladium, platinum, or composite electroplating to give threaded pogo pins excellent corrosion resistance in humid or high temperatures. Compared with other brands, Johoty has stronger anti-corrosion, which can significantly extend pogo pin lifespan, reduce maintenance costs, and ensure long-term stability of customer equipment.

We provide safe delivery and flexible custom on sizes, materials, and electrical designs according to different applications. Compared with peers, Johoty can deliver threaded pogo pins that meet customer needs in a shorter time, and the price is the best, effectively helping customers reduce production cycles and inventory pressure.

Johoty strictly controls the quality of every batch of threaded pogo pins, from the selection of brass and stainless steel to CNC machining, to various final tests, with detailed records to ensure reliable quality. Unlike its competitors, Johoty provides full traceability, allowing customers to access quality information at any time throughout the entire lifecycle, most clients can believe Johoty is trust and secure.

Why Johoty's Threaded Pogo Pins As Priority?

Johoty’s threaded pogo pins are 99.9% reliable with exceptional conductivity, boost efficiency by 20% for over 100 companies. Fast global delivery means no delays for your project. Choose Johoty as a trustworthy partner!

Threaded Pogo Pins Applications

High-security Connection of Medical Equipment

In medical equipment, threaded pogo pins are used to connect monitors and diagnostic instruments. Due to its precise threaded structure and high stability, it can provide reliable electrical connections to prevent equipment failures or interruptions. The European and American medical industries have extremely high requirements for safety and durability, and Johoty’s threaded pogo pins can meet this demand, ensuring the long-term stable operation of medical equipment.

High-Frequency Contact Applications in Automation Equipment

Threaded pogo pins are used as high-frequency contact points for automation equipment, robots, and automated production lines. Its precise connection performance can ensure high-frequency electrical signal transfer and support efficient production operations. Compared with other products, Johoty’s threaded pogo pins have stronger anti-interference and durability, greatly improving production efficiency and stability.

Connection Application of Precision Electronic Equipment

Johoty threaded pogo pins for mobile phones SOS and battery connection for tablets and smartwatches. Its high-precision thread ensures stable electrical connections and can withstand frequent plugging and vibration, greatly improving the reliability of customer equipment. Compared with traditional connections, threaded pogo pins can reduce signal interference and improve device performance, which is highly favored by European and American customers.

High-Reliability Connections in Aerospace Industry

Threaded pogo pins are used in aerospace equipment to connect various precision instruments and sensors. Due to its excellent anti-vibration and anti-interference, threaded pogo pins can withstand high voltage and vibration in extreme environments, ensuring safety and stability during flight. This high reliability makes it an indispensable connecting device in the European and American aerospace industries.

FAQ

What are Threaded Pogo Pins?

Threaded pogo pins are spring loaded pins with threads used for electrical connections and fixation. They enhance connection firmness through threaded design, making them suitable for precise installation and repeated connections. They are commonly used in electronic signals or power, charging interfaces, module connections, etc., and have both conductive and fixed functions.

What is Purpose of Threaded Pogo Pins?

Used for electronic devices, module docking, and fast charging interfaces. Its threaded design ensures firm fixation and avoids loosening or instability caused by vibration. In addition, they can effectively improve contact stability, ensure data transfer and smooth current, and support multiple installations.

Does Threaded Pogo Pins Support Customization?

Johoty provides perfece customization including size, spring force, thread specifications, and contact materials. We can fine tune specs based on acctual needs to ensure precise matching of applications. Customized services provide higher efficiency and cost-effectiveness, adapting to industrial and commercial needs.

What Working Principle Do Threaded Pogo Pins Have?

Apply pressure through internal springs to ensure a stable connection with the target contact surface. The threaded part is used to lock pogo pin to prevent detachment or misalignment. The contact part is made of conductive brass or stainless steel to ensure stable current. The spring structure supports more than 10,000 compression uses, extending its service life.

What are Specs of Threaded Pogo Pins?

The specifications include the length, diameter, sroke, thread type, rated current/voltage, and spring force. The length is usually 6-70 mm, and diameter is 0.8-2.0 ms. Thread types can be customized, available in M1-M12. The spring force from 20g to 500g, supporting diverse needs.

Is Installation of Threaded Pogo Pins Complicated?

Easy to install, supports manual and automatic tool operation. Quick installation and reduced operation time through thread design. No additional fixation after installation to maintain stability. Modular design adapts to multiple devices and reduces debug complexity. Flexible and efficient installation.

What Materials are Threaded Pogo Pins?

Contact plunger tip is brass, stainless steel, or composite materials. Its threaded structure is suitable for materials of different hardness, ensuring a tight connection. Conductive parts are gold plating and silver plating to improve contact reliability. Spring design can adapt to small deformations of various materials.

What is lifespan of Threaded Pogo Pins?

The typical lifespan is between 10,000-200,000 cycles of compression, depending on the usage environment and material selection. High quality stainless steel and gold-plated surfaces can improve lifespan. The spring strength maintains long-term stability and supports high-frequency use. Anti corrosion design extends lifespan.

Benefits Clients

High-precision Production Ensures Stability

Johoty’s threaded pogo pins are processed using 5-axis CNC to ensure precise dimensional tolerances of ± 0.01 millimeters. High precision design ensures reliable conductivity and connection stability in practical applications. Whether it is high-frequency use or complex electrical equipment connection, excellent performance can be achieved.

Long-life Spring Supports High-frequency Use

The piano steel spring and 23 quality inspections have enabled the compression life of threaded pogo pins to reach over 50000 cycles. Fearless of high-intensity testing environments, ensuring precise and reliable connections every time, providing continuous and stable support for customer devices.

Diversified Specs Meet Different Needs

Johoty offers a variety of specifications from needle length and diameter to spring force and thread types, fully supporting customization. Standardized design and flexible customization are more suitable for fast delivery, meeting high requirements for fastening and conductivity performance.

Material Selection Ensures Excellent Quality

Threaded pogo pins are made of durable materials such as gold-plated and stainless steel, with excellent corrosion resistance and adaptability to harsh environments. High conductivity and low resistance ensure stable current transmission, making customer equipment operate more safely and reliably.

Flexible Delivery Shortens Production Cycle

With a mature supply chain and automated processes, Johoty promises fast delivery. Some threaded pogo pins are in stock, and customized products are also produced efficiently to meet urgent customer needs to the maximum extent possible, reduce waiting time, and help the project run smoothly.

Strict Tests Ensure 100% Reliability

Threaded pogo pins pass 23 strict tests before leaving Johoty, including contact impedance, durability, and thread locking. Ensure threaded pogo pins received by customers meet or even exceed the standards, providing customers with reliable quality assurance.